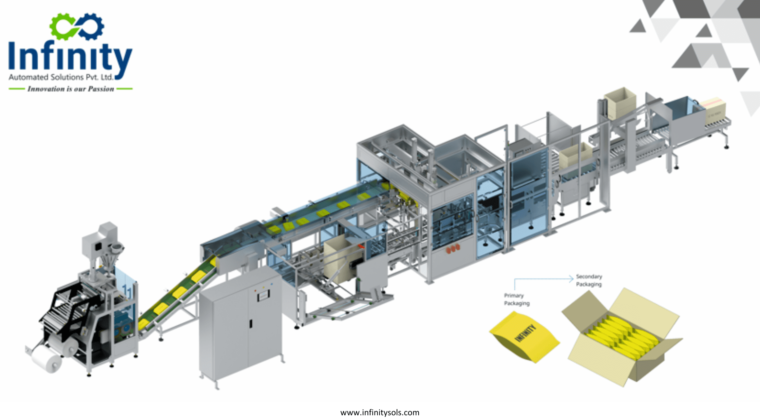

An automatic box packing machine, also known as an automatic carton packing machine or box packaging machine, is a piece of industrial equipment designed to automate the process of packing products into boxes or cartons. These automatic box packing machines are commonly used in manufacturing and distribution facilities to increase efficiency, reduce labor costs, and improve the consistency of packaging.

Here are some key features and components commonly found in automatic box packing machines:

- Conveyor System: A conveyor system transports products from the production line to the packing station. It can be designed to accommodate various types and sizes of products.

- Product Orientation and Alignment: Depending on the product’s shape and size, the machine may include mechanisms to orient and align the products correctly before packing.

- Box or Carton Supply: These machines typically have a magazine or storage area where flat boxes or cartons are stored. The machine can retrieve these boxes and set them up for packing.

- Pick-and-Place Mechanism: A robotic or mechanical arm is used to pick up individual products and place them into the boxes. This mechanism can be equipped with sensors and vision systems to ensure accurate placement.

- Filling and Cushioning: Some machines may include mechanisms for adding cushioning materials or additional product inserts, such as foam, bubble wrap, or paper, to protect the products during shipping.

- Box Sealing and Closure: After the products are placed in the boxes, the machine may automatically fold, seal, and close the boxes using various methods like tape, glue, or staples.

- Labeling and Printing: Some machines can also print and apply labels, barcodes, or date codes to the boxes for tracking and identification purposes.

- Quality Control and Inspection: Vision systems and sensors can be integrated to inspect the products and packaging for defects or discrepancies.

- Control System: An electronic control system manages the entire packing process, ensuring that it operates efficiently and according to preset parameters.

- Customization and Flexibility: Many automatic box packing machines are designed to handle a variety of box sizes and product types, offering flexibility for different production needs.

The benefits of using automatic box packing machines include increased production speed, reduced labor costs, improved product consistency and quality, and the ability to operate continuously without breaks. These machines are commonly used in industries such as food and beverage, pharmaceuticals, consumer goods, and e-commerce, where packaging efficiency is crucial to meet customer demands.

Types of Automatic Box Packing Machine

Automatic box packing machines come in various types and configurations, each designed to suit specific packaging needs and industries. Here are some common types of automatic box packing machines:

1. Cartoning Machines:

- Horizontal Cartoners: These machines are used for loading products horizontally into cartons. They are commonly used for packaging items like cereal boxes, soaps, and cosmetics.

- Vertical Cartoners: Vertical cartoning machines are ideal for filling products into cartons in a vertical orientation. They are often used for products like bags of chips or pouches.

2. Case Packing Machines:

- Wrap-Around Case Packers: These machines form a wrap-around case from a flat sheet of cardboard and then fill it with products. They are suitable for packing items like bottles, cans, and jars.

- Top-Load Case Packers: Top-load case packers load products into pre-formed cases from the top. They are commonly used in industries like pharmaceuticals and food processing.

3. Pick-and-Place Robots:

- Robotic pick-and-place systems use robots to pick up products and place them into boxes or cartons. These systems are highly flexible and can be adapted for various product shapes and sizes.

4. Palletizing Machines:

- Palletizing machines are used for loading cartons or boxes onto pallets in a specific arrangement. They are commonly used in warehouses and distribution centers to prepare products for shipping.

5. Tray Packing Machines:

- Tray-packing machines are designed to load products into trays or blister packs. They are frequently used in the pharmaceutical and healthcare industries.

6. End-of-Line Packaging Systems:

- These systems encompass a combination of machines, including cartons, case packers, sealers, and palletizers, to automate the entire packaging process from product filling to palletizing.

7. Continuous-Motion vs. Intermittent-Motion Machines:

- Continuous-motion machines operate continuously, allowing for higher production speeds.

- Intermittent-motion machines operate in a start-stop fashion, which can be more suitable for certain types of products or packaging requirements.

8. Specialized Machines:

- Some industries require specialized box packing machines designed for unique packaging challenges. For example, the pharmaceutical industry may use blister card packaging machines, while the food industry may use cup filling and sealing machines.

9. Robotic Systems:

- Robotic systems can be customized to handle a wide range of packing tasks. They offer flexibility and precision in handling products and placing them into boxes or cartons.

10. Sachet Packing Machines:

These machines are used to automatically pack small, single-use sachets or pouches into boxes for products like sugar, coffee, or condiments.

11. Multihead Weighing and Filling Machines:

- These machines weigh and fill products such as snacks, nuts, and granular items into boxes or bags with high accuracy.

The choice of an automatic box packing machine depends on factors like the type of product being packaged, production volume, packaging requirements, and industry regulations. Manufacturers and packaging engineers select the most appropriate type of machine to optimize their packaging processes and meet customer demands.

Applications of Automatic Box Packing Machine

Automatic box packing machines have a wide range of applications across various industries due to their ability to automate and streamline the packaging process. Here are some common applications of these machines:

1. Food and Beverage Industry:

- Packaging of cereal boxes, snack bags, and frozen food items.

- Filling and sealing of jars, bottles, and cans.

- Packing of confectionery items like chocolates and candies.

2. Pharmaceutical Industry:

- Packaging of pharmaceutical tablets, capsules, and vials.

- Cartoning of blister packs and pouches.

- Packaging of medical devices and healthcare products.

3. Cosmetics and Personal Care Products:

- Packaging of cosmetics and beauty products into boxes or cartons.

- Filling and sealing of tubes, bottles, and jars.

4. Consumer Goods:

- Packaging of household products like detergents and cleaning agents.

- Box packing of personal care products, toiletries, and hygiene items.

5. E-commerce and Fulfillment Centers:

- Packing of online orders into boxes for shipping.

- Box packing of a wide variety of products, including electronics, clothing, and accessories.

6. Automotive Parts and Manufacturing:

- Packaging of automotive components and spare parts.

- Cartoning of small parts and accessories.

7. Electronics Industry:

- Packaging of electronic gadgets and devices.

- Filling and sealing of boxes containing electronic components.

8. Beverage Industry:

- Packaging of beverage bottles, cans, and cartons.

- Case packing of beverages for distribution.

9. Chemical and Industrial Products:

- Packaging of chemicals, lubricants, and industrial supplies.

- Cartoning of industrial tools and equipment.

10. Textile Industry:

- Packing of clothing items, textiles, and fabrics into boxes.

- Cartoning of garments and fashion accessories.

11. Toy Industry:

- Packaging of toys and games into boxes.

- Filling and sealing of toy packaging.

12. Medical Supplies and Equipment:

- Packaging of medical supplies, instruments, and equipment.

- Cartoning of medical kits and devices.

13. Agricultural Industry:

- Packing of agricultural products like seeds, fertilizers, and pesticides.

- Packaging of gardening tools and equipment.

14. Pet Food Industry:

- Packaging of pet food and pet care products.

- Cartoning of pet food pouches and containers.

15. Stationery and Office Supplies:

- Packing of stationery items, office supplies, and school supplies into boxes.

- Cartoning of pens, pencils, and writing instruments.

16. Hardware and DIY Products:

- Packaging of hardware tools, DIY kits, and construction materials.

- Filling and sealing of boxes containing hardware items.

Automatic box packing machines are versatile and can be adapted to suit the specific requirements of each industry and product type. They help improve efficiency, reduce labor costs, and ensure consistent and accurate packaging, making them an essential component in modern manufacturing and distribution operations.