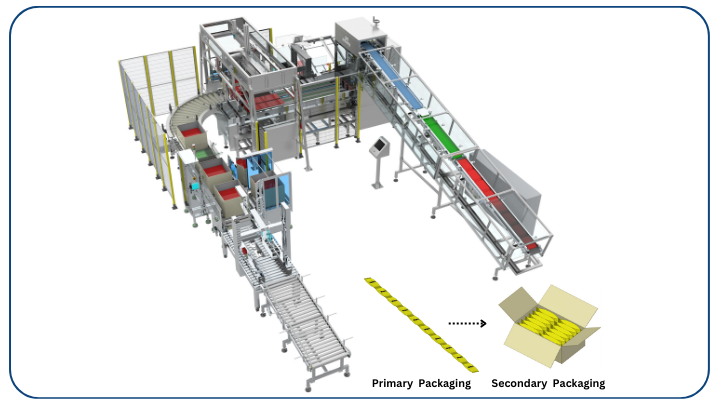

Automated Case Packer for Strip of Pouches (ICS-200)

Infinity introduces the Automated Case Packer for Strip of Pouches (ICS-200), designed to handle strips of pouches with ease, whether they are pillow bags or flat pouches. This 100% servo-driven case packaging system is meticulously crafted to meet the rigorous demands of modern packaging, seamlessly integrating with high-speed primary VFSS or HFFS lines.

Applications: Automated Case Packer for Strip of Pouches (ICS-200)

Automated case packer for strip of pouches, such as those offered by Infinity Automated Solutions, have several applications in various industries. Here are some common applications of automated case packers for strip pouches:

- Food and Beverage Industry: Automated case packer for strip of pouches are widely used in the food and beverage industry to pack products such as snack bars, candy, coffee pods, condiment packets, and single-serve pouches of sauces or beverages. These machines can handle high volumes of products, ensuring efficient packing and reducing labor costs.

- Pharmaceutical and Healthcare Industry: In the pharmaceutical and healthcare sector, an automated case packer for strip of pouches is utilized to pack strip pouches containing medications, medical devices, or personal care products. These machines ensure accurate and efficient packaging, maintaining product integrity and complying with regulatory requirements.

- Cosmetics and Toiletries: Automated case packer for strip of pouches are employed in the cosmetics and toiletries industry to package items like sample-sized products, travel-sized toiletries, or individual pouches of cosmetic products. Automated systems can handle different shapes and sizes of pouches, offering flexibility and consistency in packing.

- Household Products: Companies producing household products, such as cleaning agents, detergents, or air fresheners, often utilize Automated case packer for strip of pouches. These machines facilitate the packaging of strip pouches, ensuring proper arrangement and protection of products during transportation and storage.

- Pet Food and Treats: Automated case packer for strip of pouches are also used in the pet food industry to package treats, snacks, or small portions of pet food. These machines ensure the efficient packing of strip pouches, maintaining product freshness and preventing damage.

Experience the Future of Packaging:

Revolutionize your packaging process with our Automated Case Packer for Strip of Pouches. Contact us today to learn more about how this innovative solution can elevate your operations to new heights of efficiency and productivity.