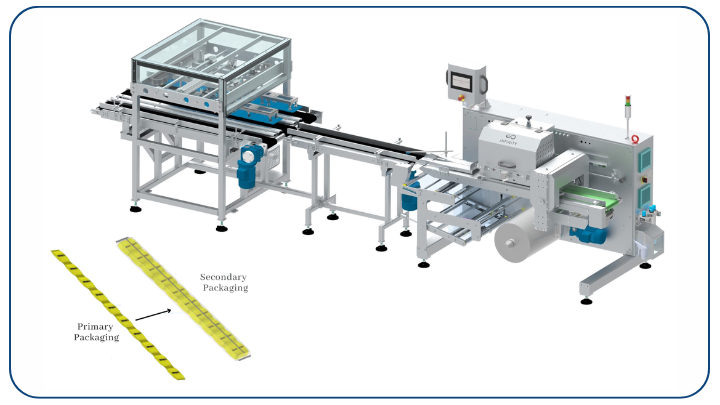

Secondary Packaging for Strip of Pouches (IBS-200)

Infinity’s Secondary Packaging for Strip of Pouches (IBS-120) serves to either stack product strips or collate them, facilitating the creation of neatly flow-wrapped packages at high production rates. Crafted from Heat Sealable Laminate, these secondary packs ensure product integrity and presentation.

The Secondary Packaging for Strip of Pouches comprises a conveyor linked to the output of the VFFS machine, an intermediate conveyor for pouch alignment, and a matrix conveyor for producing matrixes to feed into horizontal flow wraps. Employing Infinity’s cutting-edge PICK & PLACE system, ensures gentle product transfer, precise handling, and swift changeovers.

With a maximum input speed of 100 packs per minute from VFFS, the system outputs 8-12 secondary packs per minute, seamlessly integrating with VFFS and HFFS machines. Sensor-based technology guarantees accurate product counting, ensuring that 100% of quality-assured products reach customers. Tailored to meet clients’ specific requirements and application areas, our secondary packaging solutions prioritize functionality and efficiency.

Key Features: Secondary Packaging for Strip of Pouches

- High-Speed Packaging: With cutting-edge technology, our machine can package strips of pouches at remarkable speeds, enhancing your productivity and reducing time-to-market.

- Versatility: Whether you’re dealing with pharmaceuticals, food products, or any other industry requiring pouch packaging, our machine accommodates various pouch sizes and shapes.

- Precision Engineering: Every aspect of our machine is meticulously crafted for precision, ensuring that each pouch is perfectly sealed and packaged to your specifications.

- User-Friendly Interface: Our machine boasts an intuitive interface, making it easy for operators to set parameters, monitor the process, and troubleshoot any issues quickly.

- Space-Saving Design: Despite its powerful capabilities, our machine is compact, saving valuable floor space in your production facility.

- Durability and Reliability: Built with robust materials and subjected to rigorous quality control, our machine is designed to withstand the demands of continuous operation, ensuring minimal downtime.

- Compliance and Safety: We prioritize compliance with industry standards and regulations, as well as the safety of operators. Rest assured that our machine meets all necessary requirements.

Benefits: Secondary Packaging for Strip of Pouches

- Increased Efficiency: By automating the secondary packaging process, our machine significantly reduces manual labor, allowing your workforce to focus on more valuable tasks.

- Cost Savings: The efficiency and reliability of our machine translate into cost savings over time, optimizing your production expenses and maximizing profitability.

- Enhanced Quality Control: With precise packaging parameters and consistent performance, our machine helps maintain the quality and integrity of your products, fostering customer satisfaction and loyalty.

- Scalability: As your business grows, our machine can scale alongside it, accommodating increased production volumes without compromising efficiency or quality.

- Competitive Advantage: Stay ahead of the competition by investing in state-of-the-art technology that streamlines your packaging process, allowing you to meet market demands promptly and efficiently.

Applications: Secondary Packaging for Strip of Pouches

Secondary packaging for strip of pouches machines finds applications across various industries. Here are some examples:

- Food and Beverage Industry: Secondary packaging for strip of pouches is commonly used in the food and beverage industry to package items such as snacks, candy, granola bars, and individual drink pouches. It helps protect the product, maintain freshness, and provide branding and marketing opportunities.

- Pharmaceutical and Healthcare Industry: In the pharmaceutical and healthcare sectors, the secondary packaging machine is essential for packaging items like single-dose medication pouches, medical devices, and hygiene products. It ensures product safety, integrity, and compliance with regulatory requirements.

- Personal Care and Cosmetics Industry: Secondary packaging for strip of pouches is used in the personal care and cosmetics industry to package items such as face masks, makeup wipes, individual skincare pouches, and sample-sized products. It enhances product presentation, protects against contamination, and aids in branding.

- Consumer Goods and Household Products: Secondary packaging for strip of pouches is employed for a wide range of consumer goods and household products, including cleaning wipes, detergent pods, air freshener pouches, and small appliances. It helps in organizing and displaying products on store shelves and provides protection during transportation.

- Automotive and Industrial Supplies: In the automotive and industrial sectors, secondary packaging is used for packaging small parts, components, tools, and lubricants. It helps in organizing and categorizing items for easy identification, handling, and storage.

- Electronics and Technology: Secondary packaging is utilized for packaging small electronic components, accessories, cables, and consumer electronics. It ensures product safety during shipping, protects against static discharge, and enhances the overall presentation.

- Pet Care Industry: Secondary packaging for strip of pouches is employed in the pet care industry for packaging pet food samples, treats, and small pet accessories. It helps in maintaining product quality, brand recognition, and convenience for pet owners.

- E-commerce and Retail: Secondary packaging plays a vital role in e-commerce and retail operations. It enables efficient packaging of individual items or sets of products for shipping, protects against damage during transit, and provides branding opportunities to enhance customer experience.

- Innovation: We pride ourselves on being at the forefront of packaging technology. Our machine incorporates the latest innovations to ensure optimal performance, efficiency, and reliability.

- Customization: We understand that every business has unique packaging requirements. Our Secondary Packaging for Strip of Pouches machine can be tailored to meet your specific needs, whether it’s adjusting packaging parameters or integrating with existing production lines.

- Expertise: With years of experience in the packaging industry, we have the knowledge and expertise to provide top-notch solutions. Our team of engineers and technicians is dedicated to delivering exceptional products and outstanding customer support.

- Quality Assurance: Quality is our top priority. Our machines undergo rigorous testing and quality control measures to ensure they meet the highest standards of performance, durability, and safety.

- Cost-effectiveness: Investing in our machine offers long-term cost savings through increased efficiency, reduced labor costs, and minimized product waste. We offer competitive pricing and flexible financing options to accommodate your budget.

- Reliability: Our Secondary Packaging for Strip of Pouches machines is built to last. With robust construction and dependable components, you can rely on our machine to deliver consistent performance day in and day out, minimizing downtime and maximizing productivity.

- Customer Satisfaction: We prioritize customer satisfaction above all else. From initial consultation to installation and beyond, we are committed to providing exceptional service and support to ensure your complete satisfaction with our product.