Material Handling Systems / Material Handling Equipment

At Infinity Automated Solutions, we design and deliver innovative material handling systems that ensure smooth, controlled, and efficient movement of products across secondary packaging and end-of-line operations.

Our material handling solutions are engineered to integrate seamlessly with packaging machines, enabling higher throughput, reduced downtime, and consistent performance in demanding production environments.

Smart Material Handling for Secondary Packaging Automation

Efficient material handling is critical to achieving a balanced and high-speed packaging line. Infinity's systems are designed to manage product flow between processes such as bundling, wrapping, cartoning, case packing, and palletizing, ensuring uninterrupted operations.

From single product transfer to complex multi-lane conveying, our solutions support a wide range of product types, pack formats, and production speeds.

Our Material Handling Solutions Include

- Customized Conveying Systems for pouches, cartons, bottles, jars, boxes, and bundles

- Product Accumulation & Buffer Conveyors to prevent line stoppages

- Transfer, Merging & Diverting Systems for smooth product flow

- Integrated Handling Solutions for secondary packaging and end-of-line automation

All systems are designed for reliability, flexibility, and easy integration with existing and new packaging lines.

Key Benefits

- Improved line efficiency and throughput

- Reduced manual handling and operator dependency

- Smooth product flow with minimal jams

- Seamless integration with packaging machinery

- Flexible design for multiple SKUs and future expansion

Industries We Serve

Infinity's Material Handling Systems are widely used across:

- FMCG

- Food & Beverage

- Pharmaceuticals

- Personal Care

- Automotive & Industrial Products

Why Infinity Automated Solutions

With over a decade of experience and 800+ successful installations, Infinity Automated Solutions is a trusted partner for secondary packaging automation and material handling systems in India.

We offer complete end-of-line automation under one roof, delivering solutions that combine engineering excellence, innovation, and long-term operational value.

Driving Efficient & Reliable Packaging Lines

Infinity continuously develops smart and efficient material handling solutions to meet evolving production, supply chain, and marketing demands. Our focus on performance, reliability, and customer satisfaction ensures every system delivers measurable results.

All Material Handling Models

Compact overview. No technical specs.

Flat Belt Conveyor

Versatile Product Transfer and Connection System

Engineered for versatile product transfer applications, connecting primary production lines with downstream operations. Features ergonomic design, two-stage height adjustment, and variable speed control with batching capabilities.

Modular Conveyor

High-Capacity Interlocked Plastic Segment Conveyor

Conveys high loads at high speed using interlocked plastic segments that are easily replaceable. Available in multiple chain widths and styles with robust MS/SS construction.

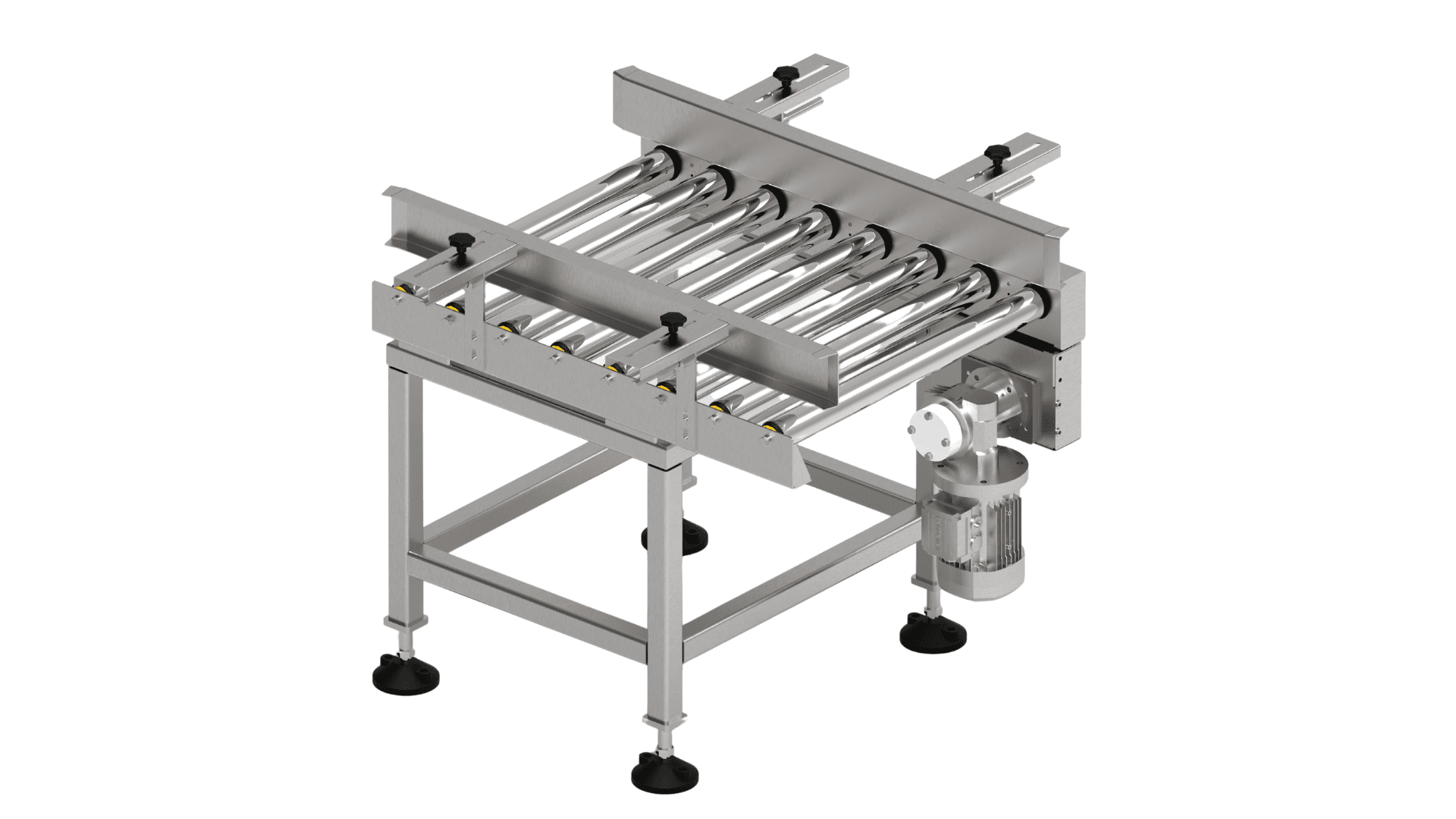

Roller Conveyor

Power Roller Conveyor for High-End Automation

Designed for product handling and interconnecting products during automation with ergonomic features, variable speed control, and durable construction.

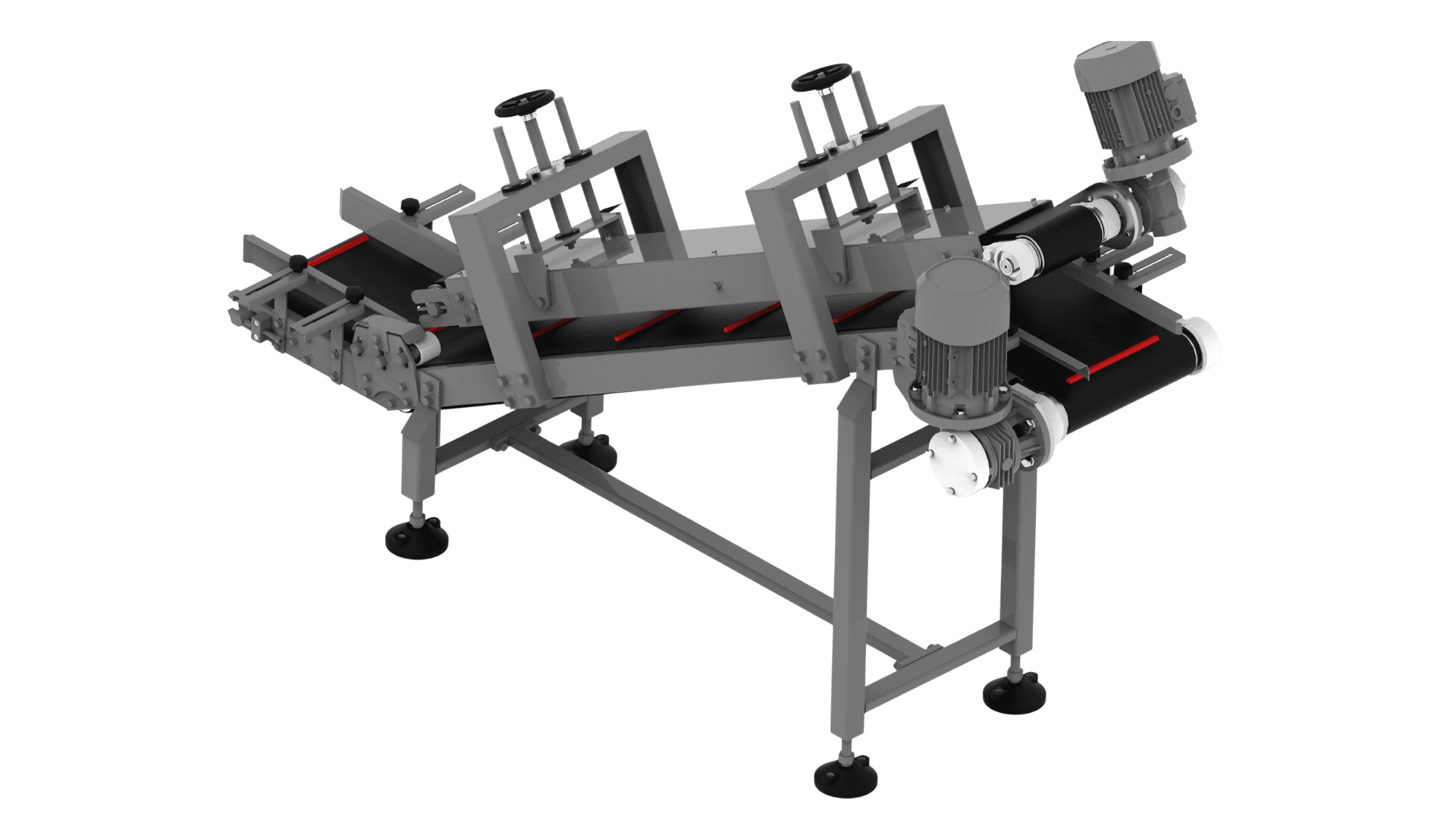

Compression Conveyor

Air Removal and Pouch Flattening System

Removes excess air from packed pouches and flattens them for compact, uniform handling. Dual parallel conveyors with adjustable compression gap for consistent results.

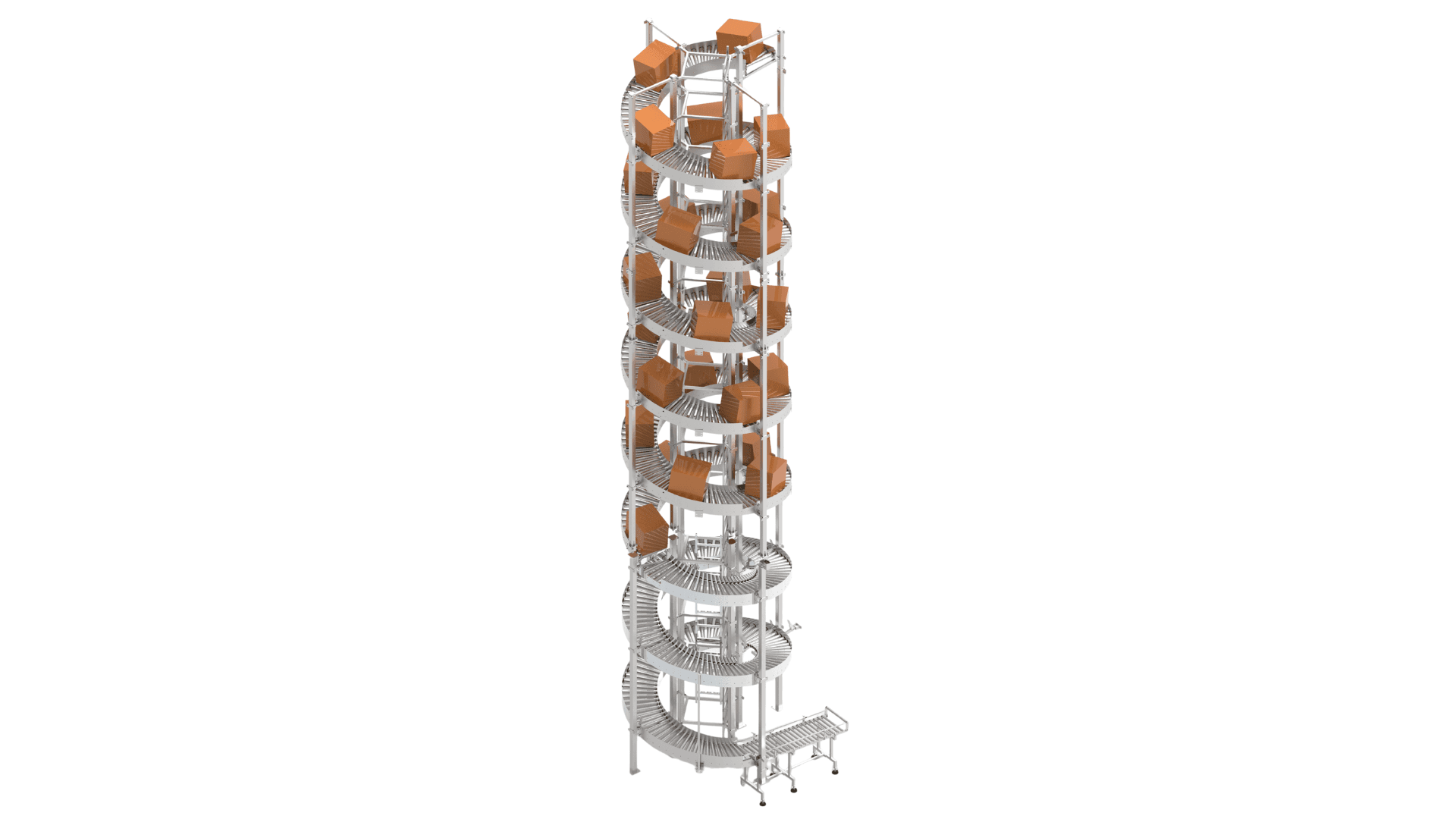

Spiral Conveyor

Space-Efficient Gravity-Driven Conveying Solution

Space-saving vertical conveying with gravity-driven continuous flow for cartons, cases, trays, and packaged goods. Faster and more reliable than lifts.

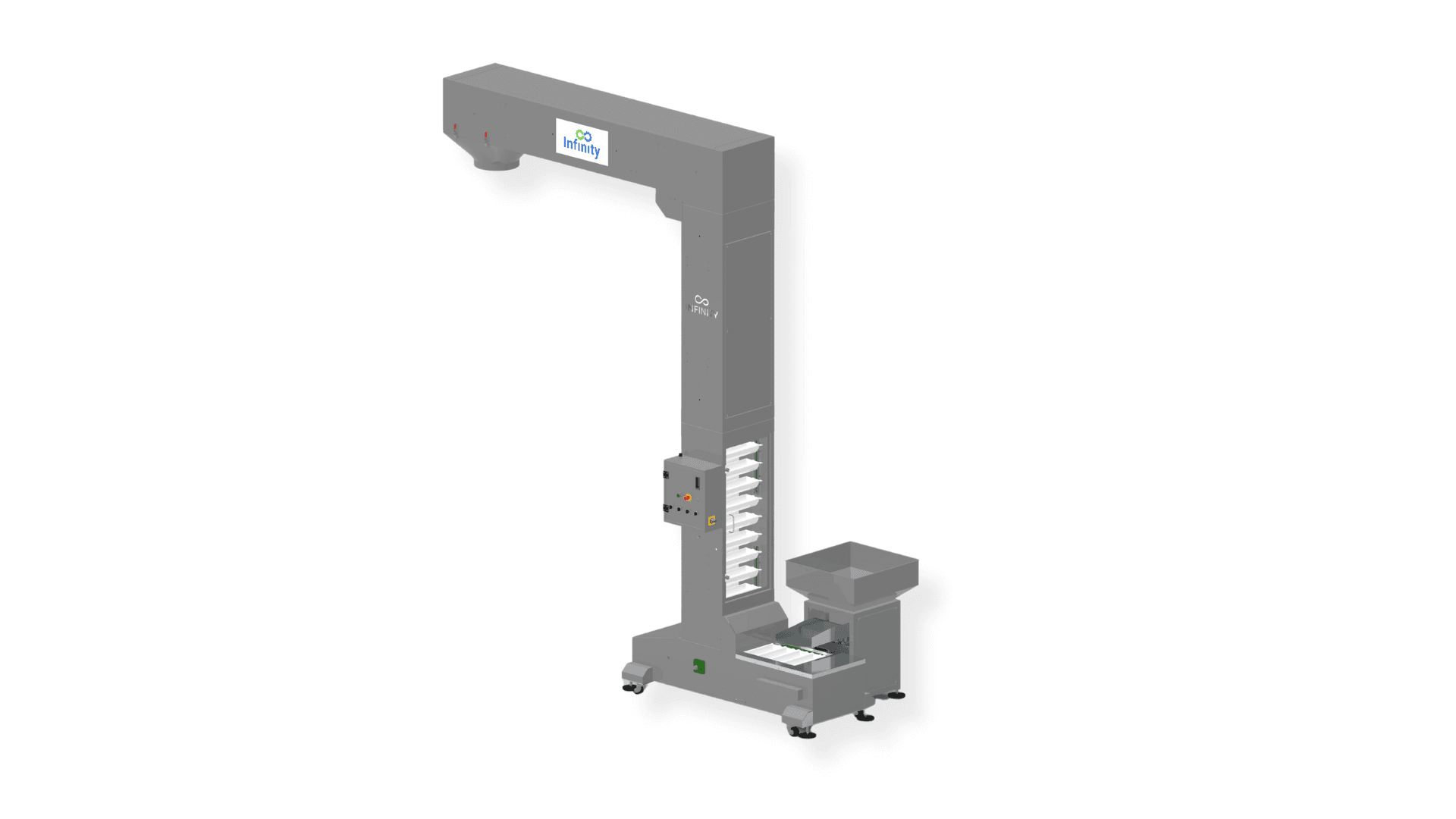

Z Type Bucket Elevator

Silent Operation Vertical Conveying Solution

Versatile vertical conveying for grains, snacks, and crystalline non-sticky materials with VFD control and food-grade construction options.

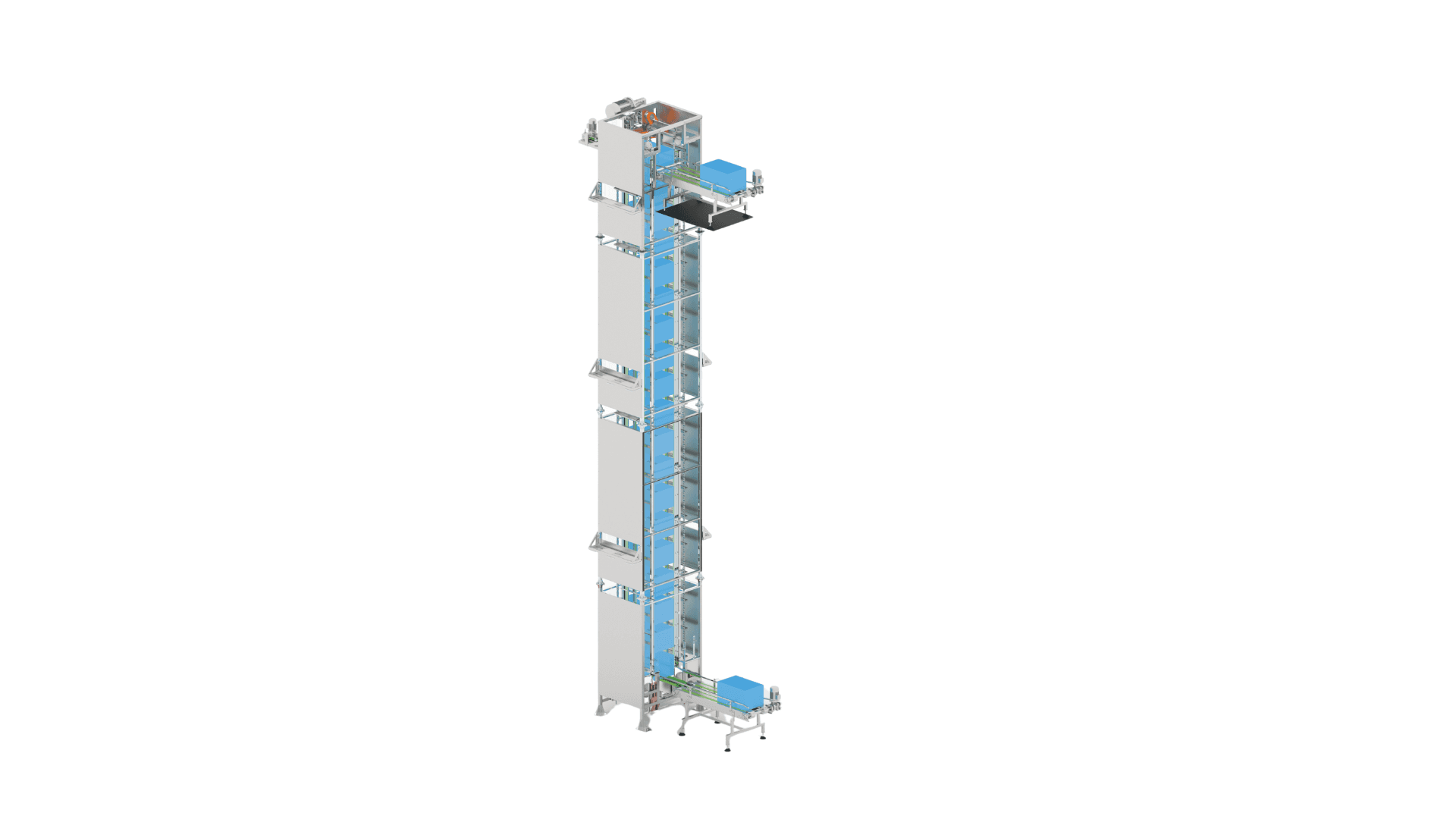

Crate/Box Lifter

Vertical Material Transfer Solution

Efficient lifting of cartons or crates to specified height for loading into palletizers. VFD-controlled operation with robust construction.

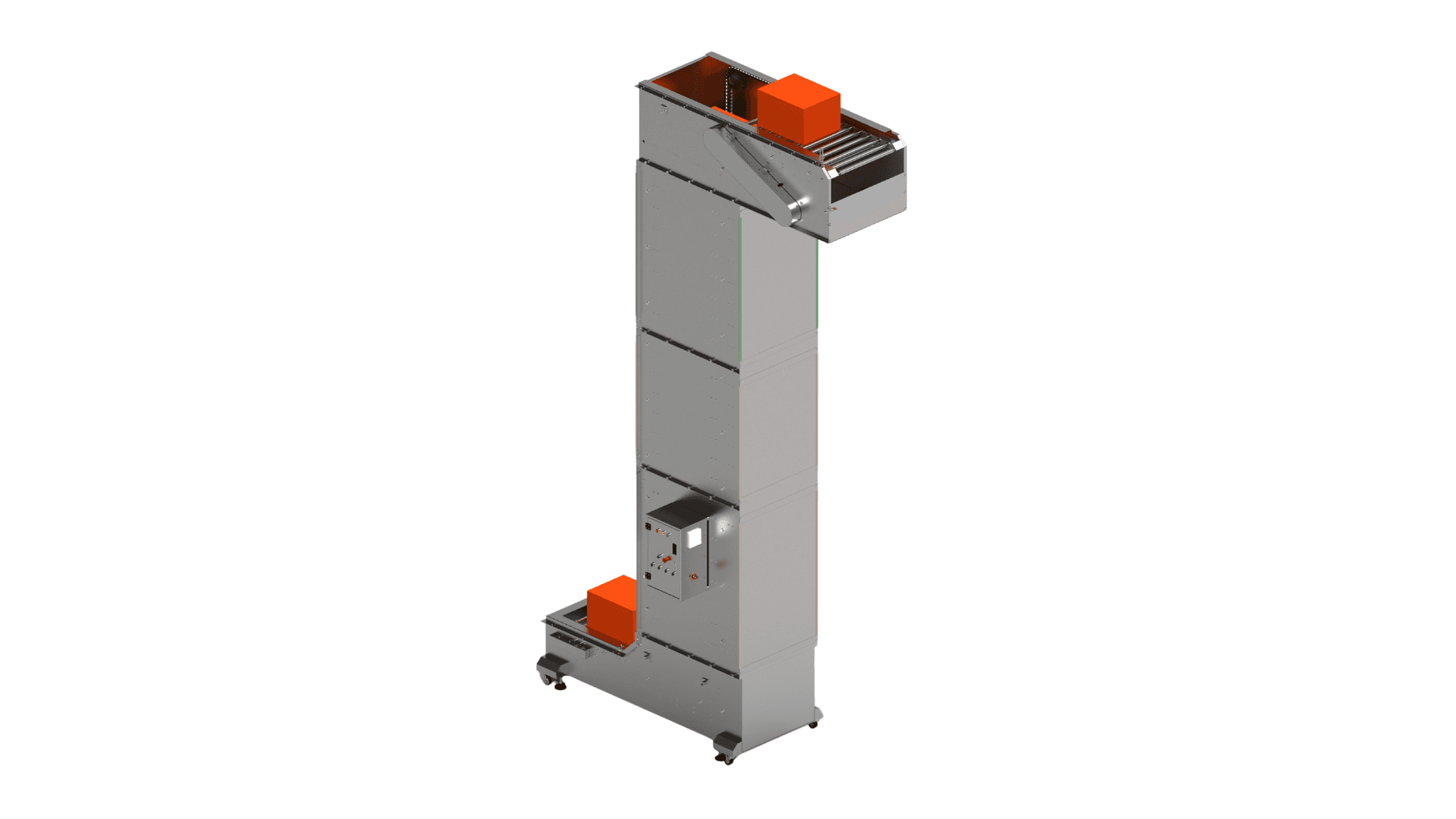

Box Lifter

High-Speed Vertical Material Transfer Solution

Automatic up-and-down movement of boxes with throughput up to 50 crates per minute and discharge heights up to 12 meters.

Need help choosing a material handling solution?

Talk to our experts for guidance on throughput, layout, and integration.