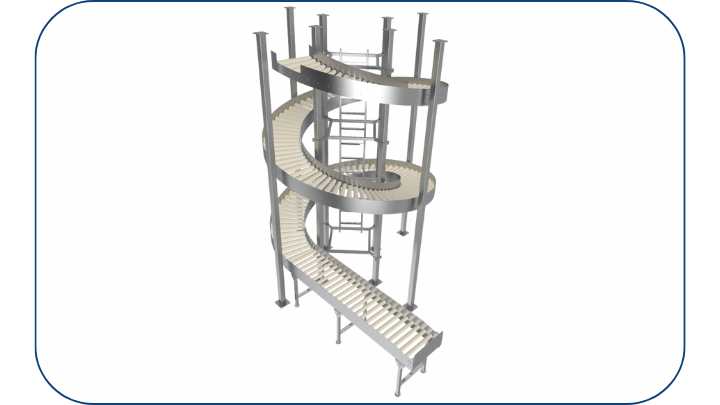

Spiral Conveyors

Infinity’s Spiral Conveyors embody cutting-edge technology, boasting a plethora of features and advantages. Capable of seamlessly conveying both full and empty cartons, cases, trays, totes, and various packaged goods in a continuous flow, they represent a paradigm shift in conveyor systems. Compared to traditional conveyors, Infinity’s spiral conveyors require less floor space while offering superior speed and reliability compared to elevators or lifts. At the heart of our design are our patented slat-type belts, engineered to provide rolling friction without any sliding movements or wear strips.

Each spiral conveyor comes standard with an automatic chain tensioning device and built-in overload protection, ensuring optimal performance and safety. This design allows for high speeds, reduced energy consumption, minimal noise output, low maintenance requirements, and extended operational lifespan. Our commitment is to deliver products with a low total cost of ownership, making them ideal for warehousing and order-picking operations.

Furthermore, all Infinity Spirals feature a horizontal section at both the infeed and outfeed points, guaranteeing a secure and reliable transition between the spiral and adjoining conveyors, thereby preventing product damage and minimizing wear.

Revolutionize Your Material Handling with Spiral Conveyors

Are you looking to optimize your material handling processes with efficiency and space-saving solutions? Look no further than our top-of-the-line Spiral Conveyors. Designed with precision engineering and cutting-edge technology, our spiral conveyors offer unparalleled performance, reliability, and versatility for a wide range of industries.

Key Features:

- Space-Saving Design: Our spiral conveyors are ingeniously designed to maximize vertical space utilization, making them ideal for facilities with limited floor space. With a compact footprint, you can increase your throughput without expanding your facility.

- High Throughput: Engineered for efficiency, our spiral conveyors can handle high volumes of materials with ease. Whether you’re transporting packages, boxes, or containers, our conveyors ensure smooth and continuous flow, minimizing downtime and maximizing productivity.

- Customizable Configurations: We understand that every application is unique. That’s why our spiral conveyors are fully customizable to meet your specific requirements. From size and configuration to speed and load capacity, we tailor our solutions to fit your exact needs.

- Gentle Product Handling: With gentle and controlled handling, our spiral conveyors are suitable for fragile or delicate products. Advanced design features ensure smooth transportation without damage, maintaining product integrity throughout the handling process.

- Durable Construction: Built to withstand the rigors of industrial environments, our spiral conveyors are constructed from high-quality materials and components. With minimal maintenance requirements, you can rely on our conveyors for long-term performance and durability.

- Easy Integration: Seamlessly integrate our spiral conveyors into your existing material handling systems. Whether you’re retrofitting an existing facility or designing a new layout, our conveyors offer flexible integration options for hassle-free installation.

Benefits of Spiral Conveyors:

- Space Optimization: Spiral conveyors are designed to maximize vertical space utilization, allowing you to make the most of your facility’s footprint without expanding horizontally. This space-saving design is particularly beneficial for facilities with limited floor space.

- Increased Throughput: With their efficient and continuous flow, spiral conveyors can handle high volumes of materials, significantly increasing throughput compared to traditional conveyor systems. This higher throughput helps improve overall productivity and operational efficiency.

- Customization Options: Spiral conveyors offer a high degree of customization, allowing you to tailor the conveyor’s size, configuration, speed, and load capacity to suit your specific application requirements. This flexibility ensures that the conveyor system seamlessly integrates into your existing workflow.

- Gentle Product Handling: Spiral conveyors provide gentle and controlled handling of products, making them suitable for transporting fragile or delicate items. This minimizes the risk of damage to goods during transportation, ensuring product integrity and reducing waste.

- Durability and Reliability: Constructed from high-quality materials and components, spiral conveyors are built to withstand the rigors of industrial environments. Their durable construction and minimal maintenance requirements contribute to long-term reliability and cost-effectiveness.

- Efficient Integration: Spiral conveyors are designed for easy integration into existing material handling systems, whether you’re retrofitting an existing facility or designing a new layout. This seamless integration reduces installation time and minimizes disruptions to your operations.

- Versatility Across Industries: Spiral conveyors find applications across a wide range of industries, including manufacturing, warehousing, distribution centers, food processing, and packaging. Their versatility makes them suitable for various material handling tasks, from transporting packages and boxes to moving food products and components.

Applications of Spiral Conveyors

Spiral conveyors are versatile and efficient material handling systems that are widely used in various industries. Here are some applications of spiral conveyors provided by Infinity Automated Solutions:

- Vertical Transportation: Spiral conveyor are commonly used for the vertical transportation of materials within a limited footprint. They can move items between different levels in a production facility or warehouse, saving valuable floor space. The continuous spiral design allows for a smooth and continuous flow of goods.

- Accumulation and Buffering: Spiral conveyors can act as accumulation and buffering systems, allowing for temporary storage of items. This is particularly useful when there is a mismatch between production rates or when downstream processes require intermittent feeding. The spiral design ensures proper sequencing and controlled release of products.

- Cooling and Freezing: Spiral conveyor can be designed to operate in temperature-controlled environments, making them suitable for cooling or freezing applications. They are commonly used in the food and beverage industry to bring down the temperature of products after cooking or baking or to freeze products for storage or transportation.

- Material Handling in Limited Space: Spiral conveyors are an ideal solution when space is limited, and traditional straight conveyors are not feasible. The spiral design enables efficient use of vertical space, allowing for the transportation of goods between different floors or levels without requiring long conveyor runs.

- Distribution and Warehousing: Spiral conveyor are utilized in distribution centers and warehouses for the efficient handling of products. They can be integrated into sorting and order fulfillment systems, facilitating the movement of goods from one area to another. Spiral conveyors can help optimize storage density and enhance order-picking processes.

- Packaging and Bottling: Spiral conveyor play a crucial role in packaging and bottling applications. They can transport products from one stage of the packaging process to another, such as moving bottles from the filling station to the labeling or capping stations. The continuous flow and gentle handling provided by spiral conveyors are beneficial for fragile or delicate products.

- E-commerce and Retail: With the growth of e-commerce and retail operations, spiral conveyor find applications in automated storage and retrieval systems (AS/RS). They can be integrated into order fulfillment systems, enabling the efficient movement of products from high-density storage areas to picking stations, and streamlining the order processing and shipping operations.

These are just a few examples of how spiral conveyor can be applied in various industries. Their versatility, compact design, and ability to handle a wide range of products make them an integral part of many automated material handling systems.

Why Choose Us?

- Industry Expertise: With years of experience in material handling solutions, we understand the unique challenges faced by different industries.

- Quality Assurance: We adhere to stringent quality standards to deliver products that exceed expectations in performance and reliability.

- Customer Satisfaction: Our dedicated team is committed to providing exceptional service and support, ensuring your complete satisfaction with our products.

Take Your Material Handling to New Heights with Spiral Conveyors!

Experience the difference that our spiral conveyors can make in optimizing your material handling processes. Contact us today to discuss your requirements and discover the perfect solution for your business.