Automated Vision Inspection Systems

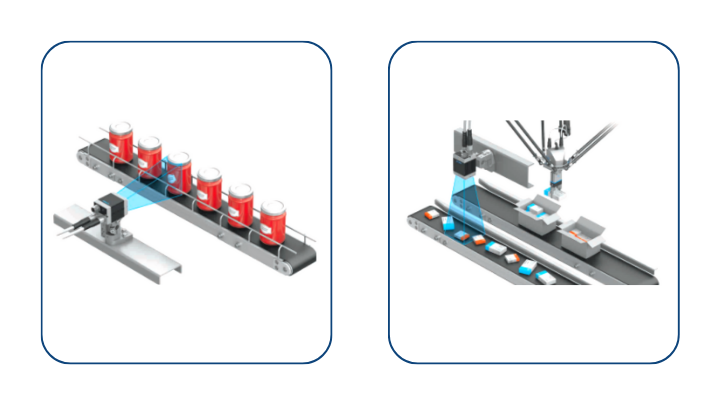

Our innovative, comprehensive, adaptable, and automated vision inspection systems offer a multitude of applications, directly benefiting the pharmaceutical industry and its stakeholders.

These machine vision systems are adept at detecting defects, contaminants, functional or printing flaws, and other irregularities in manufactured products. Examples include identifying flaws in printed data manifests, verifying icons or confirming pixel presence on displays, and measuring backlight contrast on touch screens.

Furthermore, machine vision can ensure product completeness, such as confirming the match between product and package in the food and pharmaceutical sectors, and inspecting safety seals, caps, and rings on bottles.

Designed specifically for inspection purposes, machine vision systems monitor the visual appearance of materials. Employing statistical analysis, these systems automatically identify potential defects on the material’s surface and categorize them based on similarities in contrast, texture, and/or geometry.

Most machine vision systems come equipped with a library of software tools capable of performing various types of inspections and enabling the integration of multiple inspections from captured images. The versatility and breadth of machine vision inspection are evident in the following typical tasks:

- Determining object position, such as verifying proper label placement

- Ensuring package integrity of medical products, like confirming that medicine vials are fully sealed with tamper-proof seals

- Verifying that object properties meet quality standards, such as assessing the position and volume of glue beads in automobile transmissions

- Inspecting manufactured goods and identifying flaws, including surface scratches, bent needle tips, and incomplete solder traces

- Counting items, such as products within tertiary packs, bottles in a case, and components of a kit

- Checking characteristics of completed assemblies, like the inclusion of consumer safety inserts and completion of assembly operations

Key Features:

- High-Speed Inspection: Our systems are designed to deliver lightning-fast inspection cycles without compromising accuracy, allowing you to maintain high throughput without sacrificing quality.

- Precision Detection: With cutting-edge vision algorithms and sensors, our inspection systems can detect even the most minute defects or irregularities, ensuring every product meets your stringent specifications.

- Versatile Application: Whether you’re in automotive, electronics, pharmaceuticals, or any other industry, our Automated Vision Inspection Systems can be seamlessly integrated into various manufacturing processes to streamline quality control.

- Customizable Solutions: We understand that every production line is unique. That’s why we offer customizable solutions tailored to your specific requirements, ensuring optimal performance and efficiency.

- User-Friendly Interface: Our intuitive user interface makes it easy for operators to set up, monitor, and adjust inspection parameters, reducing downtime and maximizing productivity.

- Scalability: As your business grows, our Automated Vision Inspection Systems can scale with you, accommodating increased production volumes and evolving quality control needs.

Benefits:

- Enhanced Quality Control: Minimize the risk of defects and ensure consistently high-quality products, boosting customer satisfaction and brand reputation.

- Increased Efficiency: Automating the inspection process reduces manual labor, lowers production costs, and improves overall operational efficiency.

- Data Insights: Gain valuable insights into your production process with comprehensive data analysis and reporting features, enabling continuous improvement and informed decision-making.

- Compliance Assurance: Our systems help you meet industry regulations and standards, ensuring compliance and minimizing the risk of costly recalls or fines.

Applications of Automated Vision Inspection Systems

Vision inspection systems, also known as machine vision systems, are used in various industries for automated visual inspection and quality control. These systems utilize cameras, image processing algorithms, and artificial intelligence to analyze images or videos of objects and identify defects or deviations from desired standards. Here are some common applications of vision inspection systems:

- Manufacturing Quality Control: Vision inspection systems are extensively used in manufacturing processes to ensure product quality and consistency. They can inspect products for defects such as scratches, dents, misalignments, missing components, or faulty packaging. By detecting defects early in the production line, these systems help prevent defective products from reaching consumers.

- Assembly Verification: Vision inspection systems can be employed to verify the correct assembly of components in various industries. They can detect missing parts, misplaced components, or improper connections. This helps ensure that products are assembled correctly and reduces the risk of malfunctions or safety hazards.

- Dimensional Measurement: Vision inspection systems are capable of measuring the dimensions of objects with high accuracy. They can determine length, width, height, angles, and other parameters, ensuring that products adhere to precise specifications. These measurements are vital in industries such as automotive, aerospace, electronics, and pharmaceuticals.

- Labeling and Packaging Inspection: Vision inspection system play a crucial role in verifying labels, barcodes, and packaging materials. They can identify errors such as incorrect labels, missing labels, illegible barcodes, or damaged packaging. This ensures compliance with regulations, improves traceability, and prevents product mix-ups.

- Surface Inspection: Vision inspection systems can inspect the surfaces of objects to identify flaws, defects, or contaminants. They are used in industries like automotive, glass, semiconductor, and metal manufacturing to detect scratches, cracks, stains, or uneven textures. A surface inspection ensures product aesthetics, functionality, and safety.

- Sorting and Classification: Vision inspection systems are employed for sorting and classifying objects based on their visual characteristics. For example, in the food industry, these systems can separate fruits or vegetables based on size, shape, color, or ripeness. In the recycling industry, they can sort materials like plastics, glass, or paper by their visual properties.

- Optical Character Recognition (OCR): Vision inspection systems equipped with OCR capabilities can read and interpret text from images or videos. They are used for applications like document scanning, package tracking, automatic number plate recognition (ANPR), or reading serial numbers on electronic components.

- Robotics and Automation: Vision inspection systems are integrated with robotic systems to enable automated visual guidance and inspection. They provide real-time feedback to robots, allowing them to navigate and manipulate objects accurately. This is particularly useful in tasks like pick-and-place operations, bin picking, or robotic assembly.

Why Choose Us:

- Expertise: With years of experience in the field, we have the expertise and technical know-how to deliver reliable, cutting-edge inspection solutions tailored to your needs.

- Customer Support: Our dedicated support team is committed to providing exceptional service every step of the way, from initial consultation to ongoing maintenance and support.

- Innovation: We continuously invest in research and development to stay at the forefront of technological advancements, delivering innovative solutions that keep you ahead of the competition.

Contact Us:

Ready to elevate your quality control process with our Automated Vision Inspection Systems? Get in touch with us today to schedule a consultation and discover how we can help you achieve your manufacturing goals.