Automated Case Packer for Bottles (ICB-120)

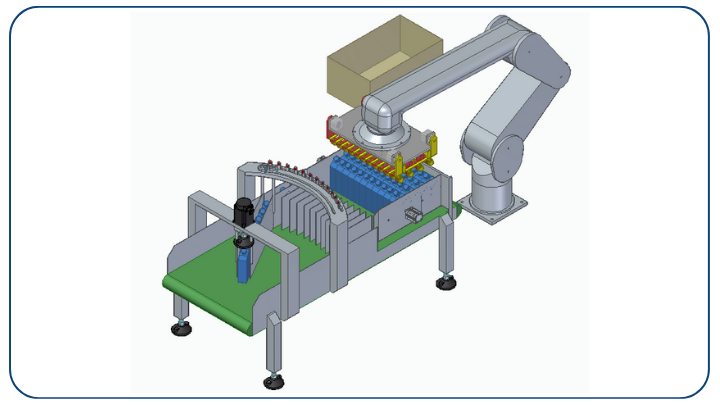

Infinity’s Automated Case Packer for Bottles (ICB-120) stands as a pinnacle of efficiency, seamlessly integrating servo-driven technology to meet the stringent demands of modern packaging. Designed to synchronize with high-speed primary bottle-filling lines, this system ensures swift, precise, and efficient packaging processes.

Guided along a high-speed conveyor, products effortlessly traverse their path, facilitated by a bespoke Robotic Pick & Place application tailored to handle and feed items into cartons with exacting precision. Employing a dual-action gripper mechanism utilizing both mechanical and vacuum suction cups, the system guarantees accurate product placement with unwavering reliability.

Augmenting its capabilities further, optional quality assurance measures, such as a weighing scale, ensure that only products meeting stringent criteria are dispatched, instilling confidence in every package delivered.

Compact yet mighty, this system boasts unparalleled flexibility within a minimal footprint, offering a compelling value proposition. Its top load pick-and-place functionality enables it to achieve remarkable throughputs while seamlessly juggling multiple tasks, all executed synchronously. From securing case flaps to deftly picking and placing products, every operation is executed within the shortest cycle times, optimizing efficiency without compromise.

Characterized by its robust construction and compact design, this system is engineered to elevate top-loading output. With carefully selected rotors adept at accommodating a variety of pack patterns at high speeds, it ensures swift and reliable packaging performance. Additionally, its open design affords operators exceptional visibility into the packaging process, facilitating rapid training and operation.

Key Features:

- High-Speed Operation: The ICB-120 is engineered for high-speed packing, capable of handling large volumes of bottles efficiently, reducing packaging time and increasing output.

- Versatile Bottle Compatibility: This case packer accommodates various bottle shapes, sizes, and materials, providing versatility to meet diverse packaging needs. Whether it’s glass, plastic, or other materials, the ICB-120 ensures seamless integration.

- User-Friendly Interface: Equipped with an intuitive interface, operators can easily control and monitor the packing process. User-friendly controls and visual indicators simplify operation and enhance productivity.

- Adjustable Configurations: The automated case packer for bottles offers adjustable configurations to adapt to different packaging requirements. From case dimensions to packing patterns, customization options ensure optimal performance and flexibility.

- Precision Packing: With precise handling mechanisms, the case packer ensures accurate placement of bottles into cases, minimizing errors and maximizing packing efficiency.

- Compact Design: Designed for space efficiency, the compact footprint of the ICB-120 makes it suitable for various production environments, optimizing floor space utilization without compromising performance.

- Robust Construction: Built with durable materials and robust components, the ICB-120 is engineered for longevity and reliability, ensuring consistent performance even in demanding production environments.

- Safety Features: Incorporating safety features such as emergency stop mechanisms and protective guards, the ICB-120 prioritizes operator safety while minimizing the risk of accidents and downtime.

Benefits:

- Enhanced Productivity: By automating the packaging process, the ICB-120 significantly boosts productivity, allowing businesses to meet growing demand without compromising quality.

- Cost Efficiency: Reduced reliance on manual labor and increased efficiency translates to cost savings in the long run, making the automated case packer for bottles a cost-effective investment for packaging operations.

- Quality Assurance: With precise packing and reliable performance, the automated case packer for bottles ensures consistent packaging quality, minimizing product damage and enhancing brand reputation.

- Adaptability: Flexible configurations and compatibility with various bottle types enable businesses to adapt quickly to changing market demands and packaging requirements.

- Streamlined Operations: The intuitive interface and automated functionalities streamline packaging operations, reducing complexity and improving workflow efficiency.

Applications of Automated Case Packer for Bottles

Automated case packer for bottles play a crucial role in the packaging industry by efficiently and accurately packing bottles into cases. Infinity Automated Solutions, as a provider of automated case packers, offers various applications for bottle packaging. Here are some common applications:

- Beverage Industry: Bottled beverages such as water, soda, juice, and energy drinks require efficient packaging solutions. Automated case packer for bottles can handle high volumes of bottles, ensuring they are properly packed into cases for shipping and distribution.

- Pharmaceutical Industry: Pharmaceuticals often come in bottle packaging, such as prescription medications, over-the-counter drugs, and vitamins. Automated case packers can carefully handle and pack these bottles to maintain product integrity and safety.

- Food and Dairy Industry: Bottled products in the food and dairy industry, including sauces, dressings, oils, and dairy products like milk and yogurt, can be efficiently packed using automated case packers. These machines can handle various bottle sizes and shapes, providing flexibility in packaging.

- Personal Care Products: Automated case packer for bottles are also utilized in the packaging of personal care items such as shampoos, conditioners, lotions, and body washes. These machines can handle different bottle materials, including plastic, glass, or metal.

- Household Cleaning Products: Bottled cleaning products like detergents, disinfectants, and multi-purpose cleaners can be packed using automated case packers. These machines ensure precise packing to avoid damage during transportation.

- Automotive and Industrial Chemicals: Automated case packer for bottles are used in the packaging of automotive fluids, lubricants, and industrial chemicals, which are often supplied in bottles. These machines can handle various bottle sizes and configurations, optimizing the packing process.

Why Choose Us?

- Expertise and Experience: We bring years of experience and expertise in the packaging industry, ensuring that our solutions are tailored to meet your specific requirements and deliver optimal performance.

- Innovative Technology: The automated case packer for bottles incorporates the latest advancements in automation and packaging technology, providing you with a cutting-edge solution that enhances efficiency, productivity, and quality.

- Customization Options: We understand that every packaging operation is unique. That’s why the Automated case packer for bottles offers customizable configurations to adapt to your production environment and packaging specifications, ensuring maximum flexibility and versatility.

- Reliability and Durability: Built with robust materials and components, the ICB-120 is designed for long-term reliability and durability. You can trust our equipment to deliver consistent performance, even in the most demanding production environments.

- Comprehensive Support: From installation and training to ongoing maintenance and support, our team is committed to providing you with comprehensive assistance every step of the way. We strive to ensure that your experience with our products is seamless and hassle-free.

- Cost-Effectiveness: Investing in the automated case packer for bottles translates to long-term cost savings. By streamlining your packaging operations, reducing labor costs, and minimizing product waste, our solution offers a significant return on investment over time.

- Commitment to Customer Satisfaction: Your satisfaction is our top priority. We go above and beyond to exceed your expectations, offering personalized service and support to ensure that you derive maximum value from our products.

- Industry Reputation: Our automated Case Packer for Bottles (ICB-120) has earned a reputation for excellence within the packaging industry. Join countless satisfied customers who have chosen our solution to optimize their packaging processes and drive business success.