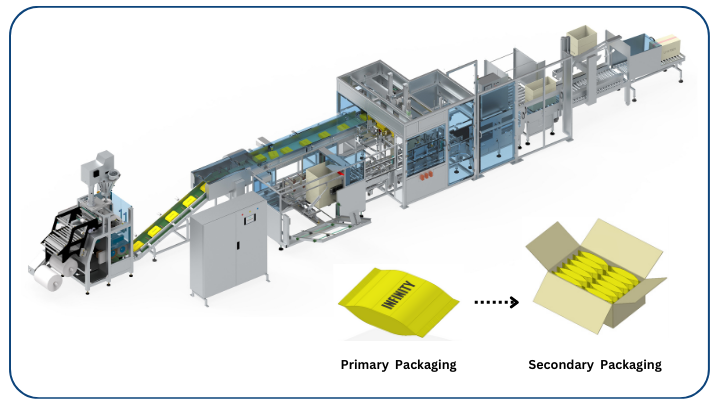

Automated Case Packer for Pouches (ICP-120)

Infinity presents the Automated Case Packer for Pouches (ICP-120), a cutting-edge, fully integrated system driven entirely by servo technology, ensuring unmatched speed, precision, and efficiency. Designed to seamlessly integrate with high-speed primary VFSS or HFFS systems, the ICP-120 revolutionizes case packaging.

Utilizing advanced conveying technology, products effortlessly undergo collation or matrix formation, while a specialized Robotic Pick & Place application guarantees precise handling and placement within cartons. For added assurance, a combination of mechanical grippers and vacuum suction cups ensures accurate product positioning.

Additionally, our system features carton erectors equipped with bottom taping, closures, and transfer capabilities for seamless workflow integration. Optional quality assurance measures, such as weighing scales, guarantee the delivery of only 100% conforming products.

Compact yet powerful, our system offers unparalleled flexibility within a minimal footprint. The top load pick-and-place machine excels in achieving higher throughputs while managing multiple tasks simultaneously. Operating in perfect synchronization, it efficiently secures case flaps, picks, and places products, all within minimal cycle times.

With its robust construction and compact design, this system significantly enhances top-loading output. Carefully selected rotors facilitate the packing of various bag configurations at high speeds, while the open design ensures clear visibility of the packaging process, facilitating operator training and enhancing operational efficiency.

Key Features: Automated Case Packer for Pouches

- Versatility: Our case packer is compatible with various pouch sizes, shapes, and materials, ensuring flexibility in packaging different products.

- High-Speed Performance: With advanced automation technology, our case packer operates at high speeds, significantly increasing your packaging throughput and overall productivity.

- Precision Packing: Equipped with precision mechanisms, our machine ensures the accurate placement of pouches into cases, minimizing errors and reducing product waste.

- User-Friendly Interface: The intuitive interface of our case packer makes it easy to set up, operate, and monitor the packaging process. Minimal training is required for operators.

- Space-Saving Design: Despite its high capacity, our case packer is designed to maximize space efficiency, making it suitable for various factory layouts and space constraints.

- Durable Construction: Built with robust materials and components, our machine is designed for long-term durability and reliable performance, minimizing downtime and maintenance costs.

- Customization Options: We understand that every production line is unique. Therefore, we offer customization options to tailor the case packer to your specific requirements, ensuring seamless integration into your existing workflow.

Benefits: Automated Case Packer for Pouches

- Increased Efficiency: By automating the case packing process, our machine eliminates manual labor, reduces production time, and boosts overall efficiency.

- Cost Savings: With higher productivity, reduced labor costs, and minimized product waste, our case packer offers substantial cost savings over time, improving your bottom line.

- Consistent Quality: The precision and accuracy of our case packer ensure consistent packaging quality, enhancing your brand reputation and customer satisfaction.

- Scalability: Our machine is designed to grow with your business. Whether you’re a small-scale operation or a large-scale enterprise, our case packer can accommodate your evolving packaging needs.

- Compliance and Safety: Our case packer complies with industry regulations and safety standards, providing peace of mind and ensuring a safe working environment for your operators.

Applications of Automated Case Packer for Pouches

Automated case packer for pouches, such as those offered by Infinity Automated Solutions, provide efficient and reliable solutions for packaging pouch-based products in various industries. Here are some applications and benefits of using automated case packers for pouches:

- Food and Beverage Industry: Automated case packer for pouches are commonly used in the food and beverage industry to pack items like pouches of snacks, confectioneries, sauces, dressings, beverages, and more. These systems can handle different pouch sizes and shapes, ensuring consistent and accurate packing.

- Pharmaceutical and Healthcare: Pouch packaging is prevalent in the pharmaceutical and healthcare sectors for products like medicines, medical devices, and hygiene items. Automated case packers can handle delicate pouches containing sensitive materials, ensuring proper handling and protection during packaging.

- Household and Personal Care Products: Many household and personal care products, such as detergents, soaps, cosmetics, and toiletries, are packaged in pouches. Automated case packers streamline the packaging process for these products, reducing manual labor and increasing productivity.

- Pet Food and Treats: The pet food industry often uses pouch packaging for treats, snacks, and small-sized pet food portions. An automated case packer for pouches can handle the pouches efficiently, ensuring accurate and consistent packing, which is essential for maintaining product quality and freshness.

- Convenience and Ready-to-Eat Meals: With the growing demand for convenience foods and ready-to-eat meals, pouch packaging has become popular. Automated case packer for pouches enables efficient packing of pouches containing individual or multi-component meals, ensuring proper sealing and labeling.