Baler Machines: In the fast-paced world of manufacturing and distribution, efficient packaging solutions are essential for businesses to stay competitive and environmentally conscious. Infinity, a trailblazer in the industry, has stepped up to the challenge with their cutting-edge baler machines. These innovative devices are transforming the packaging landscape, providing convenience, sustainability, and cost-effectiveness for businesses of all sizes.

A baler machine, also known as a baling machine or baler, is a piece of equipment used to compress and package various materials into compact, manageable bundles called bales. Balers are commonly used in recycling facilities, agriculture, manufacturing, and waste management industries to process and handle large volumes of materials efficiently. The primary purpose of a baler is to reduce the size of materials and facilitate their storage, transportation, and recycling.

The Packaging Predicament:

Traditional packaging processes often involve excessive waste, inefficiency, and high costs. Many businesses grapple with the challenge of optimizing their packaging procedures to meet both operational and environmental goals. Packaging waste not only contributes to landfills but also affects a company’s bottom line. Recognizing these challenges, Infinity set out to create a solution that would address these concerns head-on.

Enter Infinity’s Baler Machines:

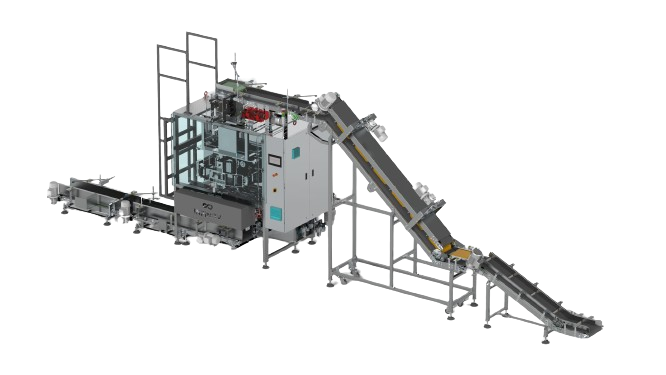

Infinity’s baler machines are a game-changer for businesses looking to streamline their packaging processes. These machines are designed to efficiently compress and bundle various types of packaging materials, including cardboard, plastic, and paper. The result is a neat and compact package that is not only easier to handle but also significantly reduces the overall volume of waste generated.

Baler machines play a crucial role in waste management and recycling, offering a range of features and benefits that contribute to efficiency, sustainability, and cost-effectiveness. Here are the key features and benefits of baler machines:

Key Features of Baler Machines:

- Material Versatility:

- Diverse Material Handling: Baler machines are designed to handle various materials, including cardboard, paper, plastics, textiles, and more. This versatility makes them adaptable to different industries and types of waste.

- Compaction Mechanism:

- Efficient Compaction: Baler machines use a compaction mechanism to compress materials into compact, manageable bales. This reduces the volume of waste, making it easier to handle, transport, and store.

- Automation and Controls:

- User-Friendly Controls: Modern baler machines are equipped with user-friendly interfaces and automation features. Intuitive controls make operation easy, allowing operators to efficiently manage the compaction process.

- Safety Features:

- Safety Sensors: Baler machines are equipped with safety features such as sensors and emergency stop buttons to ensure a secure working environment. These features help prevent accidents and protect operators.

- Bale Ejection System:

- Efficient Bale Ejection: Many baler machines have automated systems for ejecting bales. This streamlines the process and allows for continuous operation, improving overall efficiency.

- Size and Portability:

- Compact Design: Baler machines come in various sizes, including compact models suitable for smaller spaces. This flexibility allows businesses with limited space to integrate balers into their waste management processes.

Benefits of Baler Machines:

- Waste Volume Reduction:

- Space Optimization: The primary benefit of baler machines is the significant reduction in the volume of waste. Compacting materials into bales optimizes storage space, contributing to a more organized and efficient workspace.

- Cost Savings:

- Reduced Disposal Costs: By reducing waste volume, businesses can cut down on disposal costs associated with transporting and disposing of bulky, uncompressed materials. This results in direct cost savings for the company.

- Environmental Sustainability:

- Recycling Opportunities: Baler machines facilitate recycling by preparing materials for processing. This aligns with sustainability goals, reduces the environmental impact of waste, and contributes to a circular economy.

- Increased Recycling Revenue:

- Sale of Recyclables: Compacted materials are often easier to sell to recycling facilities, generating additional revenue for businesses. This financial incentive encourages companies to adopt environmentally friendly waste management practices.

- Operational Efficiency:

- Streamlined Operations: Baler machines streamline waste management processes, saving time and effort. This efficiency allows businesses to focus on core operations while meeting waste reduction and recycling targets.

- Compliance with Regulations:

- Regulatory Compliance: Proper waste management, including the use of baler machines, helps businesses comply with environmental regulations. This mitigates the risk of fines and legal consequences associated with improper waste disposal.

Baler machines find versatile applications across various industries due to their ability to efficiently compress and bundle different types of materials. Here are some common applications of baler machines:

- Packaging Industry:

- Cardboard and Paper Baling: Baler machines are extensively used in packaging facilities to compress and bundle cardboard boxes and paper waste generated during the packaging process. This helps in efficient waste management and recycling.

- Retail and Distribution Centers:

- Plastic and Packaging Materials: Retail and distribution centers utilize baler machines to compact plastic packaging materials such as shrink wrap, PET bottles, and other recyclable plastics. This aids in minimizing waste volume and facilitates recycling.

- Manufacturing Facilities:

- Metal Scrap Baling: In manufacturing processes, baler machines are employed to compress metal scrap, aluminum cans, and other metal waste into manageable bales. This not only reduces storage space requirements but also promotes recycling.

- Textile Industry:

- Textile Waste Compression: Textile manufacturing and processing units use baler machines to compress textile waste, including fabric scraps and old garments. This facilitates efficient waste disposal and may contribute to recycling efforts.

- Waste Recycling Centers:

- General Waste Handling: Waste recycling centers utilize baler machines to handle and compact mixed waste streams, enabling easier transportation and processing. This is crucial for facilities aiming to maximize recycling rates.

- Logistics and Warehousing:

- Cardboard Recycling: In logistics and warehouse operations, baler machines are employed to compress and recycle cardboard packaging materials. This helps maintain a clean and organized workspace while contributing to environmental sustainability.

- Agriculture:

- Hay and Straw Baling: Balers are widely used in agriculture to compress hay and straw into compact bales for storage and transportation. This mechanized process improves efficiency in handling and storing animal feed.

- Printing Industry:

- Paper Waste Management: Printing presses and publishing houses utilize baler machines to manage paper waste generated during printing processes. Baling helps in consolidating paper waste for easy disposal or recycling.

- Food Processing:

- Packaging Material Recycling: Food processing facilities employ baler machines to handle packaging materials like cardboard, plastic, and metal, reducing the volume of waste and facilitating recycling.

- Automotive Industry:

- Scrap Metal Handling: Baler machines are used in the automotive sector to compress and bundle scrap metal generated during manufacturing processes. This includes materials such as steel, aluminum, and other metals.

- Healthcare Facilities:

- Medical Waste Management: Healthcare institutions use baler machines to manage medical waste, such as cardboard packaging from medical supplies. This aids in maintaining a clean and sanitary environment.

- Municipal Solid Waste Management:

- Mixed Waste Baling: Balers are employed in municipal waste management facilities to compress and bundle mixed solid waste, making it easier to transport and process.

Conclusion:

Infinity’s baler machines represent a significant leap forward in the quest for efficient and sustainable packaging solutions. By addressing the challenges posed by traditional packaging methods, Infinity is empowering businesses to enhance their operations, reduce their environmental footprint, and realize cost savings. As the demand for eco-friendly practices continues to rise, Infinity’s commitment to innovation positions it as a leader in the packaging industry, driving positive change for businesses and the planet alike.