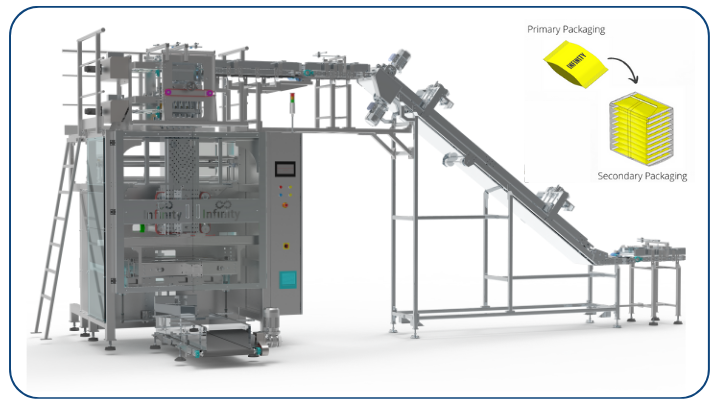

Automatic Baler Machine for Pouches (IBL-500)

Infinity’s Automatic Baler Machine (IBL-500) for Pouches streamlines the collection process, gathering products from VFFS or HFFS machines. Initially conveyed onto a high-speed conveyor, these products typically comprise large-sized pouches ranging from 0.25 kg to 2 kg. Subsequently, they undergo processing via a sandwich conveyor, precisely flattening the pouches to ensure perfect product alignment and reduce the final bagging size.

Before this stage, stringent quality control measures are implemented through the utilization of Check Weighers and Metal Detectors to uphold product integrity. The products then undergo assembly at the gate flap assembly, facilitating the creation of the desired matrix, accurate product count, and seamless entry into a secondary VFFS machine. The secondary VFFS system enables precise product counting from the gate flap assembly, ensuring easy product transfer and proper sealing for secondary bags.

The maximum input speed is an impressive 120 packs per minute from VFFS machines, while the output speed ranges between 7 to 8 secondary packs per minute. Leveraging sensor-based technology, our system guarantees precise product counting and ensures that only products meeting stringent quality criteria are delivered to customers. Additionally, the option for check-weighing further enhances quality assurance protocols.

At Infinity, we take pride in delivering tailored secondary packaging solutions that are meticulously crafted to meet our client’s specific requirements and application needs. Each solution is developed and customized, ensuring seamless integration and optimal performance across diverse operational environments.

Key Features:

- Automated Packaging: Our machine takes the guesswork out of packaging. With its advanced automation capabilities, it efficiently packs your pouch products with precision and consistency, eliminating human error and reducing product waste.

- Versatility: Whether you’re packaging snacks, pet food, hygiene products, or any other pouch-based items, our Automatic Baler Machine adapts to your needs. Its adjustable settings accommodate various pouch sizes and materials, ensuring versatility across your product range.

- High-Speed Performance: Time is money, and our machine maximizes efficiency without compromising on quality. Experience rapid packaging speeds, significantly increasing your throughput and meeting demanding production schedules with ease.

- User-Friendly Interface: Designed with simplicity in mind, our machine features an intuitive interface that minimizes training requirements. Easily set up, monitor, and adjust packaging parameters to suit your specific requirements, empowering your operators to work efficiently.

- Durable Construction: Built to withstand the rigors of industrial environments, our Automatic Baler Machine boasts robust construction and high-quality components. Count on its durability for long-term reliability and minimal downtime, ensuring uninterrupted production.

- Space-Saving Design: We understand the importance of floor space in your facility. Our compact design optimizes space utilization without compromising performance, making it suitable for facilities of all sizes.

Benefits of Automatic Baler Machine for Pouches

- Increased Efficiency: By automating the packaging process, our machine significantly reduces the time and labor required for packaging pouch products. This translates to higher productivity and throughput, allowing you to meet production demands more efficiently.

- Consistent Quality: With precise automation, our machine ensures uniform packaging of pouch products, eliminating variations caused by human error. Consistency in packaging contributes to the overall quality of your products, enhancing customer satisfaction and brand reputation.

- Cost Savings: The automation provided by our machine leads to cost savings in several areas. Reduced labor requirements mean lower labor costs, while minimized material waste results in fewer raw material expenses. Additionally, the increased efficiency of packaging operations translates to overall cost savings and improved profitability.

- Versatility and Adaptability: Our machine is designed to accommodate various pouch sizes and materials, offering flexibility to adapt to your product range. Whether you’re packaging snacks, pet food, or hygiene products, our machine can handle diverse packaging requirements, providing versatility in production.

- Streamlined Operations: Simplifying the packaging process with automation streamlines your operations, reducing the likelihood of errors and bottlenecks. This leads to smoother workflows, optimized resource utilization, and ultimately, improved operational efficiency.

- Reliability and Durability: Built with high-quality components and robust construction, our Automatic Baler Machine is engineered for durability and reliability. You can rely on its consistent performance even in demanding industrial environments, minimizing downtime and ensuring continuous production.

- Space Optimization: The compact design of our machine optimizes space utilization in your facility, allowing you to make the most of your available floor space. Whether you have a large production facility or limited space, our machine offers a space-efficient packaging solution.

- Enhanced Safety: Our machine is equipped with safety features to ensure the well-being of your operators. With automated processes, the risk of manual handling injuries and accidents is reduced, creating a safer working environment for your team.

Applications of Automatic Baler Machine for Pouches

The automatic baler machine for pouches has versatile applications across various industries. Here are some common areas where this packaging solution finds great utility:

- Food Industry: The automatic baler machine for pouches is widely used in the food industry for packaging various food products. It can efficiently handle items such as snacks, grains, nuts, coffee, spices, confectionery, frozen foods, and more. The precise product alignment and accurate counting capabilities make it ideal for maintaining product integrity and ensuring consistent packaging.

- Pharmaceutical Industry: In the pharmaceutical sector, precise and hygienic packaging is crucial. The automatic pouch baler machine for pouches can handle packaging requirements for tablets, capsules, powders, and other pharmaceutical products. The integration of quality assurance features, such as metal detectors, helps maintain strict safety standards.

- Personal Care and Cosmetics: The automatic baler machine for pouches is suitable for packaging personal care products, including creams, lotions, shampoos, gels, and cosmetic items. Its ability to align and count products accurately ensures consistent packaging presentation, enhancing brand appeal.

- Home Care Products: Various home care items, such as cleaning agents, detergents, liquid soaps, and disinfectants, can be efficiently packaged using the automatic pouch baler machine. The automatic baler machine for pouches handles different pouch sizes and ensures precise product counting for consistent packaging.

- Pet Food and Treats: The pet food industry benefits from this packaging solution as it can effectively package dry and semi-moist pet food, treats, and snacks. The system’s ability to handle large-sized pouches and accurately count products ensures efficient packaging operations.

- Agricultural and Horticultural Products: The automatic baler machine for pouches is also suitable for packaging agricultural and horticultural products like seeds, fertilizers, animal feeds, and gardening supplies. Its versatility allows it to handle different types of pouches and ensure accurate product quantities.

- Industrial and Hardware Products: This packaging solution can be applied to industrial and hardware products such as fasteners, small tools, parts, and components. The system’s precise alignment and efficient packaging process help streamline operations in these sectors.

Why Choose Our Automatic Baler Machine for Pouches?

- Enhanced Efficiency: Increase your productivity and reduce labor costs with automated packaging processes.

- Consistent Quality: Achieve uniform packaging results every time, enhancing the appeal and marketability of your products.

- Cost Savings: Minimize material waste and reduce the need for manual intervention, leading to significant cost savings in the long run.

- Reliable Support: Benefit from our dedicated customer support team, ready to assist you with installation, training, and ongoing maintenance.

Upgrade your packaging operations today with our Automatic Baler Machine for Pouches and experience the difference in efficiency, quality, and profitability. Contact us now to learn more and schedule a demonstration.