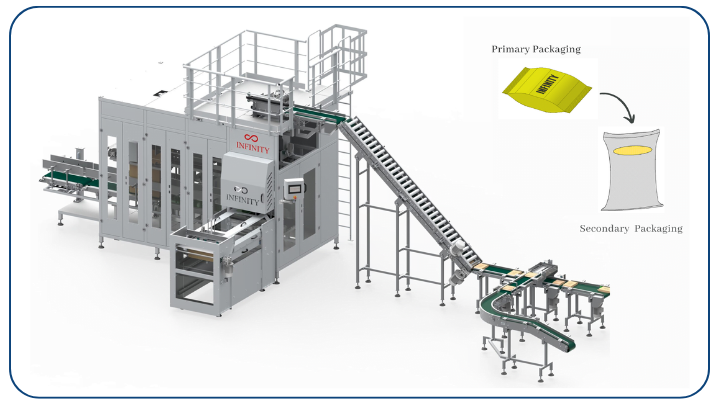

Automatic Bagging Machine (IBG-8)

The Infinity’s Automatic Bagging Machine (IBG-8) streamlines the collection process, seamlessly gathering products from either Vertical Form Fill Seal (VFFS) or Horizontal Form Fill Seal (HFFS) machines. Initially deposited onto a high-speed conveyor, these products typically consist of large-sized pouches ranging from 0.2kg to 5kg. Subsequently, they undergo processing via a sandwich conveyor, meticulously flattening the pouches to achieve precise product alignment and reduce the overall size for optimal bagging.

Before this stage, a checkpoint ensures stringent quality control measures through the utilization of Check Weighers and Metal Detectors. This ensures that only products meeting the highest quality standards proceed further. The products then undergo assembly at the gate flap assembly, facilitating the creation of the desired matrix, accurate product count, and effortless entry into HDPE sacks.

The maximum input speed stands at an impressive 120 packs per minute from VFFS machines, while the output speed ranges between 7 to 8 secondary packs per minute. Utilizing sensor-based technology, our system guarantees precise product counting and ensures that only products meeting stringent quality criteria are delivered to customers. Additionally, the option for check-weighing further enhances quality assurance protocols.

At Infinity, we pride ourselves on delivering tailored secondary packaging solutions that are meticulously crafted to meet our client’s specific requirements and application needs. Each solution is meticulously developed and customized, ensuring seamless integration and optimal performance in diverse operational environments.

Key Features:

- Fully Automated Operation: Our machine automates the entire bagging process, from filling to sealing, eliminating the need for manual intervention and minimizing the risk of errors.

- Versatility: Whether you’re packaging food products, pharmaceuticals, hardware, or any other items, our machine can handle a wide range of products with ease.

- Adjustable Settings: Customize the machine’s settings to suit your specific packaging requirements, including bag size, filling quantity, and sealing preferences.

- High-Speed Performance: With rapid processing capabilities, our machine can significantly increase your packaging throughput, saving you time and resources.

- Precision Sealing: Achieve professional-quality seals every time, ensuring product freshness and integrity throughout its shelf life.

- User-Friendly Interface: Intuitive controls make operation simple, minimizing training time and maximizing efficiency.

- Compact Design: Despite its powerful capabilities, our machine boasts a space-saving design, making it suitable for a variety of production environments.

Benefits:

- Increased Efficiency: By automating the bagging process, our machine allows you to package more products in less time, improving overall efficiency and reducing labor costs.

- Enhanced Product Quality: Consistent sealing and filling ensure that your products maintain their quality and freshness, enhancing customer satisfaction and brand reputation.

- Cost Savings: By minimizing errors and maximizing throughput, our machine helps you save on both labor and material costs, providing a rapid return on investment.

- Scalability: As your business grows, our machine can easily scale to accommodate increased production demands, ensuring continued efficiency and profitability.

Applications of Automatic Bagging Machine

The automatic bagging machine by Infinity Automated Solutions is versatile equipment used for packaging and bagging various products in the form of pouches. Here are some applications of this machine:

- Food Industry: The automatic bagging machine is commonly used in the food industry to package a wide range of products such as snacks, grains, cereals, dried fruits, and powdered food items. It provides an efficient and hygienic way of packaging food products, ensuring their freshness and quality.

- Pharmaceutical Industry: In the pharmaceutical industry, this machine is used to package medicines, tablets, capsules, and other pharmaceutical products. The machine ensures precise weighing and bagging, maintaining the integrity of the products and complying with industry standards.

- Chemicals and Fertilizers: The automatic bagging machine is suitable for bagging and packaging chemical products, including powders, granules, and solid materials. It provides a reliable and automated solution for bagging fertilizers, pesticides, detergents, and other chemical substances.

- Pet Food and Animal Feed: The automatic bagging machine is also utilized in the pet food and animal feed industry. It can package various types of pet food, including dry kibble, treats, and snacks, as well as bag animal feed for livestock, poultry, and aquaculture.

- Construction Materials: This automatic bagging machine can handle the bagging and packaging of construction materials such as cement, sand, gravel, and other bulk products. It ensures accurate weighing and sealing, improving efficiency and reducing manual labor in the construction industry.

- Agricultural Products: The automatic bagging machine is well-suited for bagging agricultural products like seeds, grains, pulses, and spices. It helps streamline the packaging process and maintain the quality and consistency of agricultural commodities.

- Home and Personal Care Products: This equipment can be used for packaging a variety of home and personal care products such as detergents, soaps, toiletries, and cleaning agents. It enables efficient and precise packaging, ensuring product safety and convenience.