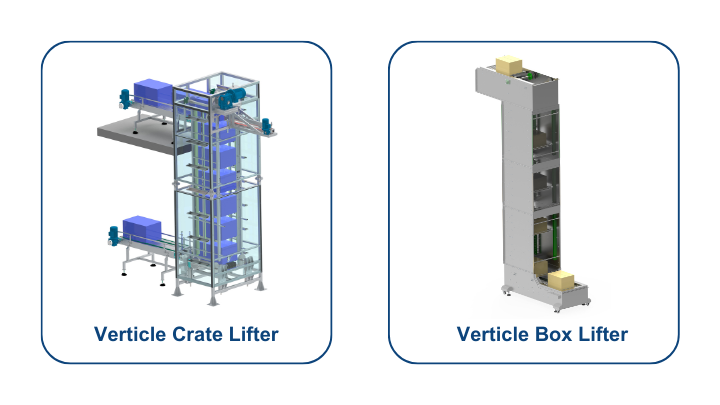

Vertical Crate Lifters and Box Lifters

Infinity Automated Solutions Pvt. Ltd. specializes in the production of a diverse array of Vertical Crate Lifters and Box Lifters, solidifying our position as the premier vertical lift conveyor manufacturer in India. Our vertical lift conveyors offer optimal solutions for lifting various types of boxes or bags to heights of up to 8 meters, boasting mobility and user-friendly operation with paramount safety features.

Tailoring our offerings to meet industry-specific demands, we craft customized vertical conveyor systems that streamline production processes, thereby reducing overall production costs while ensuring seamless and efficient operations.

Infinity’s Vertical Lift Conveyors are indispensable for elevating or lowering a wide range of items including containers, trays, packages, sacks, luggage, pallets, barrels, and more, with a sturdy surface, swiftly and consistently, even at high capacities. Whether configured in “S” or “C” setups, our conveyors operate seamlessly on a minimal footprint, enhancing productivity across various loading platforms.

Key Features of Vertical Crate Lifters and Box Lifters:

- Vertical Lifting Capability: Lift crates and boxes vertically with ease, optimizing storage space and reducing manual handling risks.

- Adjustable Design: Easily adjust the lifters to accommodate different sizes and shapes of crates and boxes, enhancing versatility and flexibility.

- Robust Construction: Constructed from high-quality materials, ensuring durability and longevity even in demanding industrial environments.

- Safety Features: Equipped with safety mechanisms such as overload protection and emergency stop functionality to prioritize operator safety.

- Efficient Operation: Streamline your material handling processes and increase productivity with smooth and reliable lifting operations.

- User-Friendly Controls: Intuitive controls make operation straightforward, minimizing training requirements for your workforce.

Benefits of Vertical Crate Lifters and Box Lifters:

- Efficiency: By utilizing vertical lifting capabilities, these lifters optimize storage space and streamline material handling processes. This efficiency can lead to increased productivity and reduced downtime.

- Safety: With built-in safety mechanisms such as overload protection and emergency stop functionality, these lifters prioritize operator safety, reducing the risk of accidents and injuries in the workplace.

- Versatility: The adjustable design of these lifters allows them to accommodate various sizes and shapes of crates and boxes, making them suitable for a wide range of applications and industries.

- Durability: Constructed from high-quality materials, these lifters are built to withstand heavy-duty use in demanding industrial environments, ensuring long-term reliability and performance.

- Cost-Effectiveness: By streamlining material handling processes and increasing efficiency, these lifters can help reduce labor costs and minimize product damage, ultimately leading to cost savings for your business.

- Ease of Operation: With user-friendly controls and intuitive design, these lifters are easy to operate, minimizing training requirements for your workforce and improving overall operational efficiency.

- Space Optimization: By lifting crates and boxes vertically, these lifters help optimize storage space in warehouses and distribution centers, allowing you to make the most of your available floor space.

- Customization Options: Optional accessories such as customized cradle attachments and remote control systems allow you to tailor these lifters to your specific needs, enhancing their versatility and functionality.

Applications of Vertical Crate Lifters and Box Lifters

Vertical crate lifters and box lifters, such as those provided by Infinity Automated Solutions, have a wide range of applications in various industries. These automated lifting systems are designed to streamline material handling processes, improve efficiency, and enhance worker safety. Here are some common applications of vertical crate lifters and box lifters:

- Warehousing and Distribution: Crate lifters and box lifters are ideal for lifting and moving crates, boxes, and other packaged goods in warehouses and distribution centers. They can efficiently transport goods from one location to another, load and unload trucks, and organize inventory on shelves.

- Manufacturing and Assembly: In manufacturing facilities, crate lifters and box lifters play a crucial role in moving raw materials, components, and finished products. They can lift heavy crates or boxes to the desired height, allowing workers to access the materials easily during assembly or production processes.

- Retail and E-commerce: In retail environments, vertical crate lifters and box lifters can be used to handle and organize merchandise. They help streamline the stocking and restocking of shelves, optimize storage space, and facilitate the movement of products from the stockroom to the sales floor.

- Food and Beverage Industry: Crate lifters and box lifters are widely used in the food and beverage industry for handling crates of ingredients, packaging materials, and finished products. They ensure smooth operations in food processing, packaging, and distribution, reducing the risk of manual handling injuries.

- Pharmaceuticals and Healthcare: Crate lifters and box lifters are valuable in pharmaceutical manufacturing and healthcare settings. They enable the safe and efficient handling of heavy crates or boxes containing medications, medical supplies, and equipment.

- Logistics and Freight: In logistics and freight operations, crate lifters and box lifters are essential for loading and unloading cargo from trucks and containers. These automated systems can efficiently move and stack crates and boxes of various sizes, improving productivity and minimizing the risk of accidents.

- Automotive Industry: Vertical crate lifters and box lifters find applications in the automotive industry for handling parts, tools, and components. They simplify the movement of heavy items during assembly, maintenance, and repair operations.

Overall, vertical crate lifters and box lifters offered by Infinity Automated Solutions, or similar providers, are versatile tools that can enhance material handling processes across different industries. They contribute to increased productivity, reduced labor costs, and improved workplace safety.

Why Choose Our Vertical Crate Lifters and Box Lifters?

- Reliability: Built to withstand heavy-duty use, ensuring consistent performance over time.

- Safety: Prioritize the safety of your operators with built-in safety features and robust construction.

- Versatility: Adapt to various material handling needs with adjustable design and optional accessories.

- Efficiency: Streamline your operations and increase productivity with efficient lifting capabilities.

- Expert Support: Count on our team for expert guidance and support throughout the product lifecycle.

Enhance your material handling processes with our Vertical Crate Lifters and Box Lifters. Contact us today to learn more and request a quote.