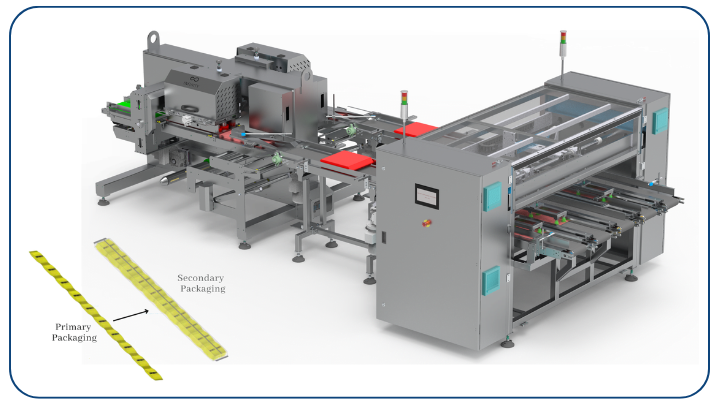

Secondary Packaging for Multitrack VFFS (IMS-800/IMS-600)

Infinity’s Automated Secondary Packaging for Multitrack VFFS (vertical form fill seal) systems is designed to efficiently collate strips of products or individual pouches from multi-track primary lines, facilitating further bundling or stacking flow-wrapping. The secondary packs are crafted using Heat Sealable Laminate materials.

This secondary packaging automation comprises a conveyor at the VFFS machine’s output, along with an intermediate conveyor to synchronize the pouches’ speed. Additionally, it incorporates a matrix conveyor for creating matrixes and supplying them to horizontal flow wraps. To ensure gentle product transfer, precise handling, and swift changeovers, the system employs Infinity’s advanced PICK & PLACE technology.

Utilizing sensor-based technology, our system accurately counts your products, guaranteeing that 100% quality-assured items are delivered to customers, with an optional check-weighing feature. Each secondary packaging solution we offer is meticulously developed and customized to meet our client’s specific requirements and application needs.

Features: Secondary Packaging for Multitrack VFFS

- Customizable Design: Our secondary packaging solutions are customizable to fit the specific requirements of your Multitrack VFFS system. We understand that every product is unique, and our packaging can be tailored to accommodate different sizes, shapes, and packaging configurations.

- Robust Construction: Built to withstand the rigors of high-speed packaging operations, our secondary packaging solutions are constructed using high-quality materials. This ensures durability and longevity, reducing downtime and maintenance costs.

- Efficient Integration: Our packaging solutions seamlessly integrate with Multitrack VFFS systems, enhancing the overall efficiency of your production line. With easy setup and minimal adjustments required, you can maximize productivity and minimize downtime.

- Enhanced Product Protection: Protect your products during transit and storage with our secondary packaging solutions. Whether it’s ensuring product freshness, preventing tampering, or providing additional layers of protection, our packaging solutions offer peace of mind.

- Sustainable Options: We are committed to sustainability and offer eco-friendly secondary packaging solutions. From recyclable materials to optimized packaging designs that minimize waste, we help you reduce your environmental footprint while meeting your packaging needs.

- Cost-Effective Solutions: Our secondary packaging solutions are designed to optimize packaging efficiency and reduce overall costs. By minimizing material usage, improving production speed, and enhancing product protection, we help you achieve cost savings without compromising on quality.

Benefits: Secondary Packaging for Multitrack VFFS

- Increased Efficiency: Streamline your packaging process and boost productivity with our secondary packaging solutions.

- Improved Product Quality: Ensure your products remain fresh and intact throughout the packaging process and during transportation.

- Versatile Applications: Our packaging solutions are suitable for a wide range of products, making them ideal for diverse industries and applications.

- Customization Options: Tailor the design and specifications of your secondary packaging to meet the unique requirements of your products and production line.

- Sustainability: Contribute to environmental conservation efforts by choosing our eco-friendly packaging solutions.

Applications: Secondary Packaging for Multitrack VFFS

Secondary packaging for multitrack VFFS are versatile packaging machines used in various industries. They are designed to efficiently package multiple products simultaneously, offering increased production capacity and flexibility. Here’s how these machines are used in different industries:

- Food Industry: Secondary packaging for multitrack VFFS is extensively used in the food industry. They can package a wide range of food products such as snacks, chips, candies, cookies, coffee, spices, and more. The multitrack feature enables simultaneous filling and sealing of multiple pouches, increasing productivity. These machines can handle different pouch sizes, shapes, and materials to cater to diverse food products.

- Beverage Industry: In the beverage industry, secondary packaging for multitrack VFFS is utilized for packaging liquid and powdered products. They can package items like juice mixes, coffee mixes, powdered drink mixes, and more. The machines efficiently fill and seal multiple pouches simultaneously, improving production efficiency. They can handle various pouch sizes and offer options for adding spouts or fitments for easy dispensing.

- Pharmaceutical Industry: Secondary packaging for multitrack VFFS finds application in the pharmaceutical industry. They are used for packaging tablets, capsules, powders, and granules. The machines ensure accurate dosing, precise filling, and reliable sealing to maintain product integrity. Multiple tracks allow for increased production capacity, making them suitable for high-volume pharmaceutical packaging.

- Personal Care and Cosmetics: A secondary packaging for multitrack VFFS is employed in the personal care and cosmetics industry. They can package products like shampoo, conditioners, lotions, creams, and powders. These machines enable efficient filling and sealing of multiple pouches, ensuring product hygiene and preventing leakage or spillage. They offer flexibility to accommodate various pouch sizes and materials to meet the packaging requirements of different products.

- Household Products: Various household products such as detergents, cleaning agents, pet care products, and more can be packaged using secondary packaging for multitrack VFFS. The machines provide efficient and reliable filling, sealing, and packaging solutions. They can handle different pouch sizes and materials, allowing for customization based on the specific requirements of household products.

- Industrial and Automotive: Secondary packaging for multitrack VFFS is also utilized in the industrial and automotive sectors. They can package items such as lubricants, adhesives, chemicals, and small automotive components. These machines offer precise dosing, accurate filling, and secure sealing to ensure product safety and prevent leakage. Multiple tracks enable higher production capacity, making them suitable for industrial and automotive packaging needs.

- Retail and E-commerce: A secondary packaging for multitrack VFFS is used in the retail and e-commerce sectors to package a variety of products. They are capable of packaging items like sample packs, trial-size products, gift sets, and promotional packs. The machines provide efficient and consistent packaging solutions while maintaining the visual appeal of the packaged products.

Why Choose Us?

With years of experience and a commitment to excellence, we are your trusted partner for all your secondary packaging needs. Our team of experts will work closely with you to develop customized solutions that meet your specific requirements and exceed your expectations.

Experience the difference our secondary packaging solutions can make for your Multitrack VFFS system. Contact us today to learn more and request a consultation.