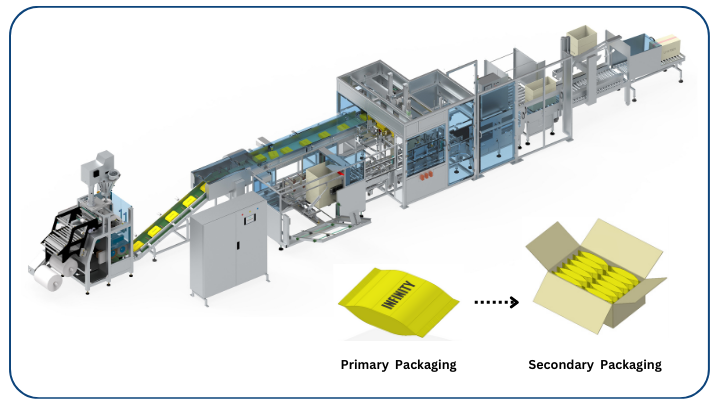

Automated Case Packer for Pouches (ICP-120)

Automated Case Packer for Pouches

At Infinity Automated Solutions, we bring smart automation to your production line with our high-performance automated case packer for pouches. Designed to streamline your end-of-line operations, our ICP-120 case packer offers unmatched speed, flexibility, and precision—helping industries scale without compromising on packaging quality.

Why Choose Our Automated Case Packer for Pouches?

- Fully Automated Process: Automates product collation, counting, and case insertion.

- Custom Configuration: Designed to handle multiple pouch sizes and case formats.

- Smart Pouch Alignment: Sandwich and gating conveyors maintain shape and uniformity.

- Integrated QA Checks: Optional metal detector and check weigher ensure only verified pouches are packed.

- Sensor-Based Technology: Ensures correct count and positioning of every pouch.

- Seamless Integration: Easily connects with your existing end-of-line systems.

Key Features of ICP-120

- Up to 120 pouch input per minute

- Outputs 7–8 complete cases per minute

- Compatible with various pouch types (food, snacks, pharma)

- Servo-driven pick & place system

- Adjustable gating and matrix formation

- Minimal floor space required

- Mitsubishi PLC and drives, Schneider switchgear

Applications of Automated Case Packer for Pouches

Our automated case packer is widely used in:

- Food & Beverages: Chips, pulses, grains, flour, ready-to-eat items

- Pharmaceuticals: Sachets, strips, powder-based pouches

- Spices & Condiments: Small pouch packs, masala sachets

- Tea & Coffee: Individual and strip pouch packs

- Dairy Products: Milk powder, ice cream mix

- Personal Care: Shampoo, face wash, and cosmetic pouches

- Pet Food & Feed: Treats, snacks, and dry feed pouches

Benefits of Infinity’s Automated Case Packer

- Boosts Packaging Speed: Keep up with high-volume pouch production lines

- Improves Packing Accuracy: Sensor-controlled systems reduce human error

- Saves Space: Compact footprint fits into tight production layouts

- Reduces Labor Costs: One system replaces multiple manual packers

- Customizable Solutions: Built to match your product, pouch size, and plant layout

- High Return on Investment: Long-term savings and increased uptime

Why Infinity Automated Solutions?

With 10+ years of packaging automation experience, Infinity is trusted by leading brands across India and abroad. Our expertise in automated case packers ensures you receive not only a machine, but a complete packaging solution—designed, tested, and supported by professionals.

- Proven across food, pharma, and consumer goods

- Made in India with global service reach

- Engineering-driven customization

- End-to-end support from design to installation

- Trusted by TATA, ITC, Marico, Suhana, Everest & more

Upgrade Your Packaging Line Today

Infinity’s automated case packer for pouches is the perfect solution for businesses looking to scale operations, improve efficiency, and ensure consistent product delivery. Whether you’re a growing brand or an established name, ICP-120 is your partner in smart packaging automation.