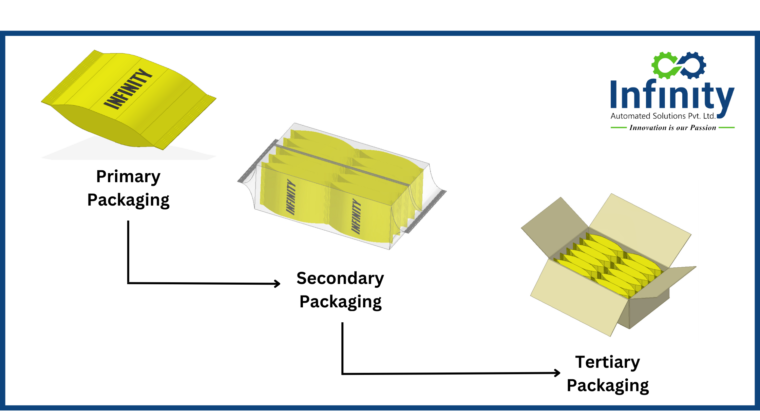

Primary Secondary and Tertiary Packaging: In the intricate dance of product distribution, packaging plays a pivotal role in ensuring that goods reach consumers intact and in pristine condition. The packaging process involves a multi-layered approach, with primary secondary and tertiary packaging each serving distinct functions in safeguarding products throughout the supply chain. In this blog post, we’ll delve into the significance of each packaging layer and how they collectively contribute to the efficiency and safety of product delivery.

Primary Secondary and Tertiary Packaging

1. Primary Packaging

Primary packaging, often referred to as the first layer of packaging or retail packaging, is the immediate enclosure that comes into direct contact with the product. This layer serves multiple essential functions, playing a crucial role in preserving the integrity of the product from the point of manufacturing to the consumer.

Functions of Primary Packaging:

- Product Protection:

- Shields the product from environmental factors such as moisture, light, air, and contaminants.

- Prevents physical damage during handling, shipping, and display.

- Preservation of Freshness:

- Maintains the freshness and quality of perishable goods, such as food and pharmaceuticals.

- Often includes features like seals and airtight packaging.

- Information and Communication:

- Displays essential product information such as ingredients, usage instructions, and nutritional facts.

- Communicates branding elements, including logos, taglines, and promotional messages.

- Consumer Experience:

- Influences the consumer’s first impression and perception of the product.

- Enhances the overall aesthetic appeal, making the product more attractive on the shelf.

- Convenience and Portability:

- Facilitates easy handling and transportation of the product by consumers.

- May include features such as handles, resealable openings, or dispensing mechanisms.

- Compliance and Safety:

- Ensures adherence to regulatory standards and safety requirements.

- Includes child-resistant packaging for certain products like medications.

Common Types of Primary Packaging:

- Bottles and Jars:

- Common for beverages, pharmaceuticals, cosmetics, and condiments.

- Offers a secure and sealed environment.

- Blister Packs and Clamshells:

- Frequently used for pharmaceuticals, electronics, and small consumer goods.

- Provides individual compartments for each unit.

- Cans and Tins:

- Ideal for food and beverage products, as well as certain industrial items.

- Offers durability and protection against external elements.

- Flexible Packaging:

- Includes pouches, sachets, and wrappers.

- Suitable for a wide range of products and often offers lightweight and cost-effective solutions.

- Boxes and Cartons:

- Common for products like cereal, electronics, and cosmetics.

- Provides ample space for branding and information.

Trends in Primary Packaging:

- Sustainable Materials:

- Growing emphasis on using eco-friendly materials to reduce environmental impact.

- Recyclable, biodegradable, or compostable packaging options.

- Smart Packaging:

- Integration of technology for features like QR codes, RFID tags, or temperature-sensitive indicators.

- Enhances consumer engagement and provides product information.

- Minimalist Design:

- Aesthetic simplicity and reduced material usage for a more sustainable and cost-effective approach.

- Focus on clean, modern designs to appeal to environmentally conscious consumers.

2. Secondary Packaging

Secondary packaging, also known as outer packaging or transit packaging, plays a crucial role in protecting and facilitating the handling of products during their journey from the manufacturer to the retailer. This layer of packaging surrounds the primary packaging, providing an additional level of protection, information, and convenience throughout the supply chain.

Functions of Secondary Packaging:

- Protection During Transit:

- Shields the primary packaging and product from external elements, such as rough handling, stacking, and environmental factors during transportation.

- Grouping and Containment:

- Packages multiple units of the product for efficient handling and transportation.

- Ensures stability and minimizes the risk of damage to individual items.

- Branding and Information:

- Offers a larger surface area for branding, allowing for more detailed graphics, marketing messages, and product information.

- Provides an opportunity to convey additional details about the product’s features, benefits, and usage.

- Retail Display:

- Facilitates easy stocking and display on retail shelves.

- Often designed to attract consumer attention and complement store aesthetics.

- Security Features:

- Includes tamper-evident seals or security measures to ensure the integrity of the product.

- Prevents unauthorized access or tampering during transportation and storage.

- Handling and Convenience:

- Incorporates features such as handles, perforations, or tear strips for easy opening.

- Streamlines the unpacking process for retailers and consumers.

- Environmental Considerations:

- Increasingly incorporates eco-friendly materials to align with sustainability goals.

- Minimizes excess packaging while maintaining structural integrity.

Common Types of Secondary Packaging:

- Cardboard Boxes and Cartons:

- Common for a wide range of products, including electronics, appliances, and non-perishable goods.

- Provides structural support and branding opportunities.

- Shrink Wrap and Stretch Film:

- Secures products together for stability during transportation.

- Offers protection against dust and moisture.

- Corrugated Boxes:

- Sturdy and versatile packaging suitable for various products.

- Often used for shipping and storing multiple units of a product.

- Pallets:

- Used for grouping and transporting large quantities of products.

- Facilitates efficient handling with forklifts and pallet jacks.

- Paperboard Sleeves:

- Enhances the visual appeal of the product on the shelf.

- Provides an additional layer for branding and product information.

Trends in Secondary Packaging:

- Eco-Friendly Practices:

- Increasing use of recyclable, biodegradable, or compostable materials.

- Exploration of innovative designs that minimize environmental impact.

- Smart Packaging Solutions:

- Integration of technology, such as RFID tags or QR codes, for supply chain visibility and consumer engagement.

- Enables tracking and tracing throughout the distribution process.

- Reduced Packaging Waste:

- Emphasis on right-sizing packaging to minimize waste.

- Implementing efficient design practices to achieve sustainability goals.

- Premium and Customized Packaging:

- Growing demand for premium secondary packaging to enhance the perceived value of products.

- Customized packaging solutions to differentiate brands and products.

3. Tertiary Packaging

Tertiary packaging, also known as shipping or transport packaging, is the outermost layer of packaging designed to protect and facilitate the efficient handling of products during bulk transportation and storage. This layer is essential for securing multiple units of products during their journey through the entire supply chain, from manufacturing to distribution centers and ultimately to retailers.

Functions of Tertiary Packaging:

- Bulk Transport:

- Tertiary packaging is specifically designed for the transportation of large quantities of products.

- Protects products during long-distance shipping and handling.

- Stability and Palletization:

- Facilitates efficient stacking and palletization of products for easy handling with forklifts and other material-handling equipment.

- Ensures stability during transportation to prevent damage.

- Protection from Environmental Factors:

- Guards against external elements such as weather, dust, and other contaminants during transit and storage in warehouses.

- Unitization:

- Combines multiple units of products into a single, easily manageable unit.

- Reduces the risk of loss or damage by keeping individual items together.

- Ease of Identification:

- Identifies the contents of the shipment, making it easy for warehouse staff to manage and distribute products.

- Facilitation of Automated Handling:

- Designed to work seamlessly with automated sorting and handling systems in distribution centers.

- Enhances the efficiency of warehouse operations.

- Security and Tamper-Evidence:

- Includes features to deter tampering and unauthorized access during transportation.

- May incorporate seals, straps, or other security measures.

Common Types of Tertiary Packaging:

- Pallets:

- Wooden, plastic, or metal platforms that provide a stable base for stacking and transporting products.

- Facilitates efficient handling in warehouses and during shipping.

- Stretch Wrap:

- Transparent plastic film is used to secure and stabilize products on pallets.

- Protects against dust and provides additional stability.

- Strapping and Banding:

- Metal or plastic straps are used to bind and secure products on pallets.

- Ensures the stability of the load during transportation.

- Corrugated Boxes:

- Larger boxes are used to pack multiple units of products for bulk transportation.

- Offers additional protection and ease of handling.

- Bulk Bags and Super Sacks:

- Large, flexible containers are often used for bulk materials.

- Facilitates the handling of powders, grains, and other granular products.

Trends in Tertiary Packaging:

- Sustainable Materials:

- Increasing use of eco-friendly materials for pallets, straps, and other tertiary packaging components.

- Focus on reducing environmental impact throughout the supply chain.

- Optimization for Automation:

- Designing tertiary packaging to align with automated warehouse systems.

- Incorporating features that enhance the efficiency of robotic handling.

- RFID and Tracking Technologies:

- Integration of RFID tags and other tracking technologies for real-time monitoring and tracing of shipments.

- Enhances visibility and control over the supply chain.

- Customization for Specific Industries:

- Tailoring tertiary packaging solutions to meet the unique requirements of different industries.

- Custom-sized pallets and packaging to optimize space and reduce waste.

Conclusion:

Understanding the nuances of primary secondary and tertiary packaging is vital for businesses aiming to optimize their supply chain processes. By implementing thoughtful packaging strategies, companies can not only protect their products but also enhance their brand image and contribute to a more sustainable future.

In the ever-evolving landscape of product distribution, the art and science of packaging continue to play a central role in shaping the consumer experience and the efficiency of global supply chains.