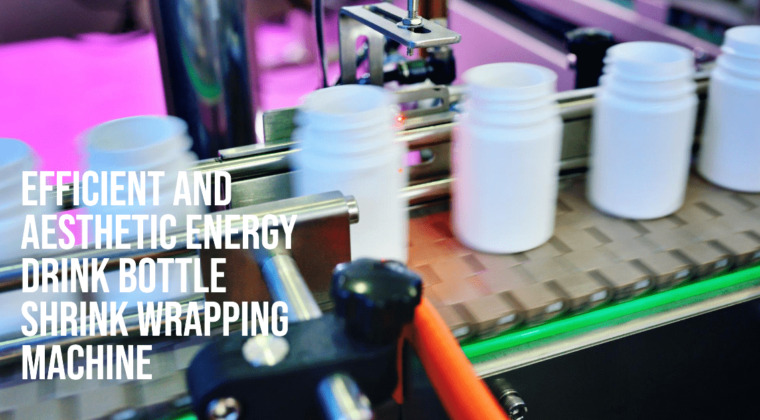

Energy Drink Bottle Shrink Wrapping Machines: In the fast-paced world of beverage manufacturing, efficiency, precision, and presentation are key factors for success. Energy drink producers, facing relentless demand and fierce competition, require innovative solutions to streamline their production processes while enhancing the appeal of their products. Enter the energy drink bottle shrink wrapping machine – a sophisticated tool designed to meet these challenges head-on. In this article, we’ll delve into the features and benefits of energy drink bottle shrink wrapping machines, highlighting their indispensable role in the beverage industry.

Download Brochure: https://infinitysols.com/service/shrink-wrapping-machine-for-bottles/

Features of Energy Drink Bottle Shrink Wrapping Machines:

- Versatility: Energy drink bottle shrink wrapping machines are engineered to handle a wide range of bottle sizes, shapes, and materials. Whether it’s sleek aluminum cans or uniquely contoured plastic bottles, these machines can adapt to various packaging requirements effortlessly.

- High-Speed Operation: In a competitive market where time is money, speed matters. Shrink wrapping machines boast high-speed operation capabilities, ensuring rapid packaging of energy drink bottles without compromising on quality or consistency.

- Automated Functionality: Gone are the days of manual packaging processes. Energy drink bottle shrink wrapping machines feature advanced automation, seamlessly handling tasks such as bottle feeding, film sealing, and heat shrinking with precision and efficiency.

- Precision Temperature Control: Maintaining the optimal temperature is crucial for achieving impeccable shrink wrapping results. These machines are equipped with sophisticated temperature control systems, ensuring consistent heat distribution for uniform shrinkage across all bottles.

- Space Efficiency: In today’s manufacturing facilities, maximizing space utilization is essential. Energy drink bottle shrink wrapping machines are designed with a compact footprint, allowing for seamless integration into existing production lines without compromising on efficiency.

Benefits of Energy Drink Bottle Shrink Wrapping Machines:

- Enhanced Brand Visibility: Packaging plays a pivotal role in capturing consumer attention and differentiating products on store shelves. Shrink wrapping machines enable energy drink brands to create visually stunning packaging designs, enhancing brand visibility and attracting customers with eye-catching presentations.

- Product Protection: Beyond aesthetics, shrink wrapping provides a robust protective barrier, safeguarding energy drink bottles against external elements such as moisture, dust, and physical damage. This ensures that the product remains pristine and fresh from production to consumption.

- Tamper Resistance: Safety and security are paramount in the beverage industry. Shrink wrapping not only protects against tampering but also serves as a visual indicator of product integrity, instilling confidence in consumers and retailers alike.

- Cost Efficiency: By automating the packaging process and minimizing material waste, shrink wrapping machines help energy drink manufacturers reduce operational costs and enhance overall profitability. Additionally, their high-speed operation translates to increased throughput and greater production efficiency.

- Sustainability: As consumer demand for sustainable packaging solutions grows, shrink wrapping machines offer a greener alternative. By using recyclable materials and optimizing packaging dimensions, these machines contribute to environmental conservation efforts while meeting regulatory requirements.

Applications of Shrink Wrapping Machines:

- Beverage Industry: The Infinity Shrink Wrapping Machine is ideally suited for the beverage industry, particularly for packaging energy drinks. From single-serving bottles to multipacks, this machine efficiently wraps and seals bottles, enhancing product presentation and shelf appeal.

- Food Packaging: Beyond beverages, the Infinity machine finds applications in the food packaging sector. Whether it’s bottled sauces, condiments, or specialty food items, manufacturers can utilize this machine to ensure product freshness and tamper-proof packaging.

- Health and Personal Care: With its versatility and precision, the Infinity Shrink Wrapping Machine caters to the health and personal care industry. From vitamin supplements to skincare products, manufacturers can package a variety of products with confidence, knowing that the packaging process is efficient and reliable.

- Promotional Packaging: The Infinity Machine opens up opportunities for creative promotional packaging campaigns. Whether it’s bundling multiple products together or incorporating custom branding elements, manufacturers can leverage this machine to captivate consumers and drive sales.

- E-commerce Packaging: In the era of e-commerce, efficient packaging solutions are essential for shipping products securely. The Infinity Shrink Wrapping Machine enables e-commerce retailers to package products with precision, ensuring they arrive at their destination in pristine condition.

Conclusion:

Energy drink bottle shrink wrapping machines are indispensable assets for beverage manufacturers seeking to streamline production processes, elevate brand image, and meet evolving consumer demands. With their versatile features and compelling benefits, these machines not only optimize efficiency and cost-effectiveness but also reinforce the commitment to sustainability. As the beverage industry continues to evolve, investing in advanced shrink wrapping technology will undoubtedly remain a strategic imperative for driving growth and staying ahead of the competition.

Infinity’s Fully Automatic Secondary Packaging Solutions:

- Pouch Bundling & Wrapping

- Automatic Pouch Baler System

- Automatic Cartoning Machine

- Automated Case Packers

For more information, Contact us

- WhatsApp or Call: +91 8484922042

- Mail: info@infinitysols.com

- Website: www.infinitysols.com