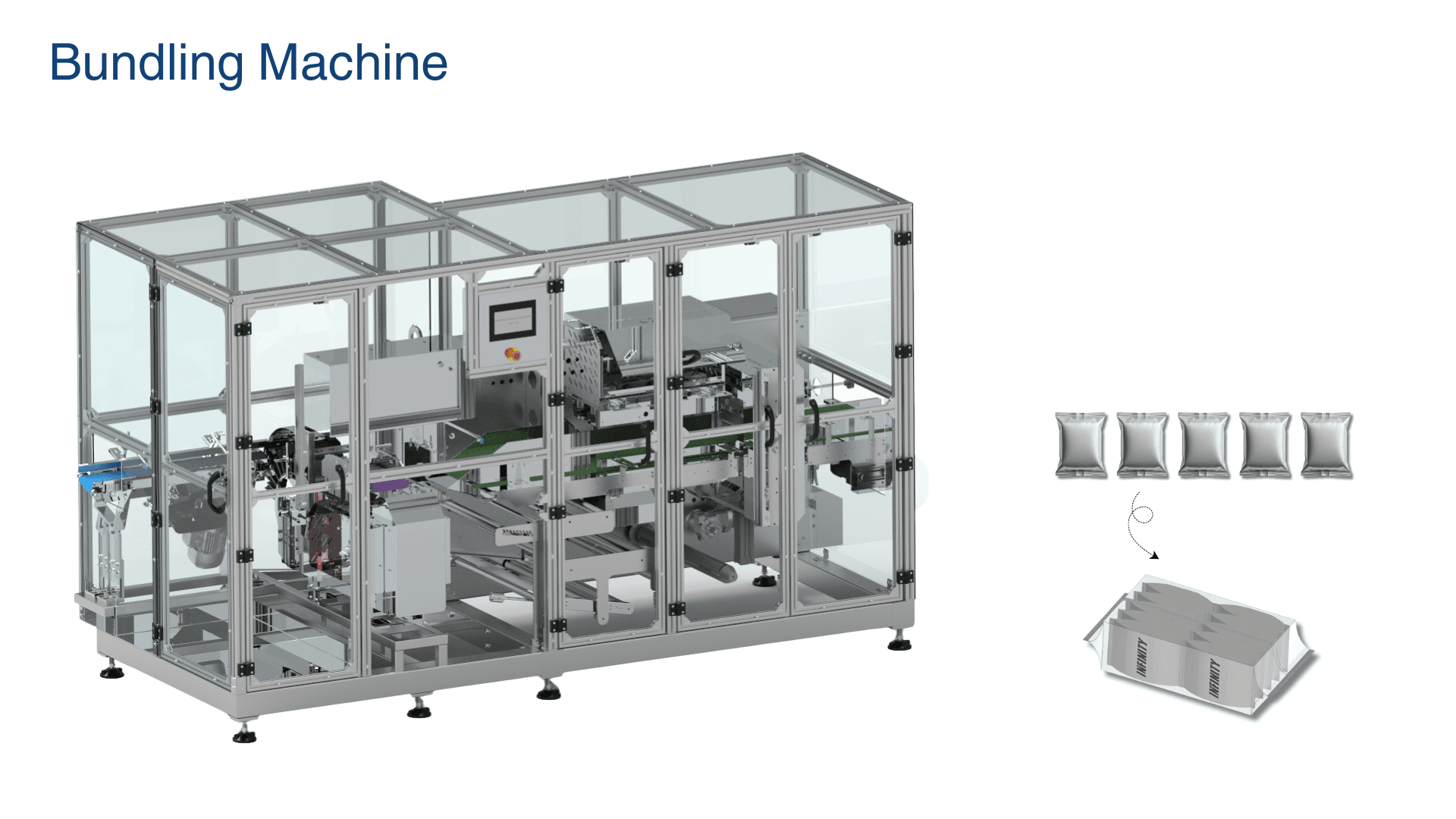

IBP-120 – Secondary Packaging Machine for PouchBundling

Product Brochure

Get detailed specifications and technical information

Quick Model Access

The IBP 120 Pouch Bundling Machine from Infinity Automated Solutions is a high-performance secondary packaging solution designed for efficient and accurate bundling of flexible pouches. This advanced pouch bundling machine is engineered to bundle individual and pouches ranging from 50 g to 1 kg into compact, secure packs for easy handling, storage, and transportation.

Certifications

IBP-120 – Secondary Packaging Machine for Pouch Bundling

IBP-120 – Secondary Packaging Machine for Pouch Bundling

The IBP-120 is a high-speed secondary packaging machine designed for accurate and efficient bundling of single pouches and 3D pouches ranging from 50g to 1 kg. Built with Infinity's advanced RACETRACK technology, the machine ensures smooth collation and delivers compact, secure secondary packs in BOPP or LDPE bags using an inverted flow-wrap system. This secondary packaging machine is ideal for industries that need consistent, high-quality pouch bundling with minimum product wastage and maximum efficiency. as a Secondary packaging machine manufacturer in India, Infinity ensures prompt service, installation, and maintenance.

Product Overview

The IBP 120 Pouch Bundling Machine from Infinity Automated Solutions is a high-performance secondary packaging solution designed for efficient and accurate bundling of flexible pouches. This advanced pouch bundling machine is engineered to bundle individual and pouches ranging from 50 g to 1 kg into compact, secure packs for easy handling, storage, and transportation. Designed to reduce manual...

Features & Capabilities

Professional GradeAdvanced Features

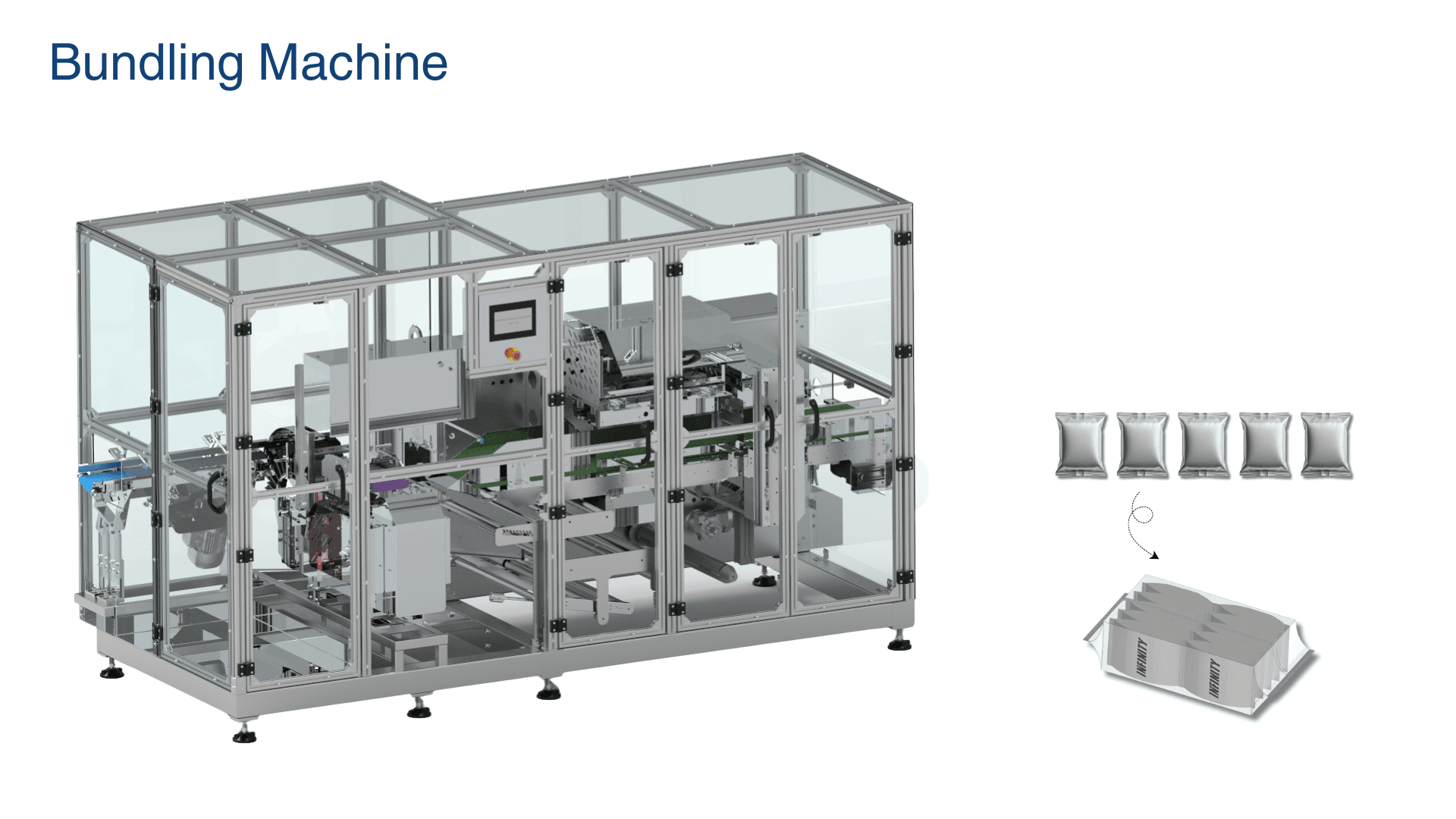

Advanced RACETRACK Collation Technology

Ensures precise, vibration-free, and stable collation of pouches before bundling.

Inverted Flow Wrap for Clean, Tight Packing

Creates strong and compact bundles using BOPP or LDPE bags, suitable for transportation and stacking.

"No Product, No Pouch" Feature

This intelligent feature prevents empty pouches from being produced, reducing material wastage and improving overall efficiency.

Compatible with Multiple Pouch Types

Works with single pouches, stand-up pouches, flat pouches, and biscuits packets.

Key Highlights

High-speed operation ideal for medium to large production lines

Compact and reliable pouch bundling output

Designed for continuous operation with minimal downtime

Smooth product flow using RACETRACK technology

Reduced manpower requirements and lower operational costs

High-speed bundling for 50g to 1 kg pouches with stable output quality

Easy integration with upstream filling and downstream case packing

Why IBP-120 is the Best Secondary Packaging

The IBP-120 stands out because it combines speed, accuracy, and automation. It is engineered to handle a wide range of pouches with consistent quality, making it one of the most reliable machines in secondary packaging operations.

Benefits for Your Packaging Line

Faster production with continuous packaging cycles

Accurate bundling with stable pack quality

Lower human dependency

Safe and strong secondary packs

Easy integration with upstream and downstream automation

Minimizes product and material waste

Frequently Asked Questions (FAQ)

What is the IBP-120 used for?

IBP-120 is used for secondary packaging and pouch bundling, especially for products between 50g and 1kg.

What materials can the machine pack?

It uses BOPP and LDPE bags for secure and compact bundling.

Does it support different pouch sizes?

Yes, it supports single pouches and products across multiple sizes and shapes.

How does the "no product, no pouch" feature help?

It stops empty bags from being created, saving material and reducing wastage.

Can the IBP-120 be connected to other machines?

Yes, it can be integrated with upstream filling machines and downstream case packers for a complete packaging line.

Related Models in secondary packaging

IBP-120

IBP-120 Pouch Bundling Machine

IBS-200

IBS-200 Strip Pouch Bundling Machine

IMS-800

IMS-800 Multitrack VFFS Handler

Ready to Get Started?

Get detailed pricing and specifications for IBP-120 – Secondary Packaging Machine for Pouch Bundling

Product Tags

Transform Your Packaging Process Today

Join 800+ satisfied customers who have revolutionized their packaging with our IBP-120 – Secondary Packaging Machine for Pouch Bundling solution.