Streamlining Pillow Bag Packaging: In the dynamic world of packaging, efficiency and precision are paramount. Infinity, a leading provider of automated packaging solutions, has designed a comprehensive range of secondary packaging solutions specifically tailored for pillow bags. From bundling to cartoning, Infinity’s innovative machines ensure seamless and efficient packaging processes. Let’s delve into the details of some of Infinity’s cutting-edge automated solutions.

Infinity’s Bundling for Pouches (IBP-200):

The IBP-200 is a high-speed bundling machine designed to efficiently group and secure individual pillow bags. With its advanced technology, this machine ensures a tight and secure bundle, maintaining the integrity of the packaging.

Infinity’s Bundling for Strip of Pouches (IBS-120):

Tailored for strip packaging, the IBS-120 provides a streamlined solution for bundling multiple pouches in a strip. This automated process enhances productivity while maintaining the aesthetic appeal of the bundled strip.

Infinity’s Shrink Wrapping for Pouches (ISP-200):

The ISP-200 is an automated shrink-wrapping solution that adds an extra layer of protection to individual pillow bags. This not only ensures product safety during transit but also enhances the overall visual appeal of the packaged items.

Infinity’s Multitrack for Strip of Pouches (IMS-600/800):

The IMS-600/800 is a versatile multitrack machine capable of handling a large volume of strip pouches simultaneously. Its efficiency and speed make it an ideal choice for industries with high production demands.

Infinity’s Baler for Pouches (IBL-500):

The IBL-500 is designed for compacting and bundling pouches efficiently. This baler not only saves space but also aids in the easy disposal of packaging material, contributing to a more sustainable packaging process.

Infinity’s Bagging for Pouches (IBG-8):

The IBG-8 is an automated bagging solution that ensures accurate and efficient packaging of pillow bags. Its user-friendly interface and precise bagging mechanism make it an essential component in any packaging line.

Automatic Cartoning Machine (ACM-100 & ACM-40):

Infinity offers two automatic cartoning machines – ACM-100 and ACM-40 – providing versatile solutions for packaging individual pouches. These machines are designed to handle various carton sizes and configurations, ensuring flexibility in packaging.

Infinity’s Case Packer for Pouches (ICP-200):

The ICP-200 is a specialized case-packing machine designed to efficiently pack pouches into cases. Its automated processes reduce manual intervention, increasing overall production efficiency.

Infinity’s Case Packer for Strip of Pouches (ICS-120):

Tailored for strip packaging, the ICS-120 automates the case packing process for strip pouches. This machine ensures that the packaged products are securely placed in cases, and ready for distribution.

Benefits of Infinity’s Automated Secondary Packaging Solutions for Pillow Bags

- Increased Efficiency: Infinity’s automated solutions significantly increase packaging line efficiency, allowing for higher production rates and reduced lead times. The machines operate seamlessly, minimizing downtime and optimizing the overall packaging process.

- Precision and Consistency: Automation ensures precise and consistent packaging, reducing the likelihood of errors associated with manual processes. This results in a higher quality of packaged products and a more professional appearance.

- Cost Savings: Automated packaging solutions can lead to substantial cost savings over time. Reduced labor requirements, minimized material waste, and increased throughput contribute to a more cost-effective and sustainable packaging operation.

- Flexibility and Adaptability: Infinity’s machines are designed to be versatile, accommodating various pillow bag sizes and configurations. This flexibility allows manufacturers to adapt to changing market demands and product specifications with ease.

- Enhanced Product Safety: Shrink-wrapping and bundling solutions provide an additional layer of protection for pillow bags, ensuring product safety during transit and storage. This contributes to customer satisfaction and reduces the likelihood of damaged goods.

- Streamlined Operations: Automation streamlines packaging operations by minimizing manual labor, reducing the risk of human error, and optimizing the use of resources. This results in a more efficient and streamlined overall production process.

- Space Optimization: The compact design of Infinity’s machines, such as the baler (IBL-500), aids in space optimization within manufacturing facilities. This is particularly crucial for businesses with limited space, allowing for efficient use of available resources.

- User-Friendly Interface: Infinity’s automated packaging solutions feature user-friendly interfaces, making them easy to operate and maintain. This ensures that operators can quickly adapt to the machinery, reducing training time and improving overall system usability.

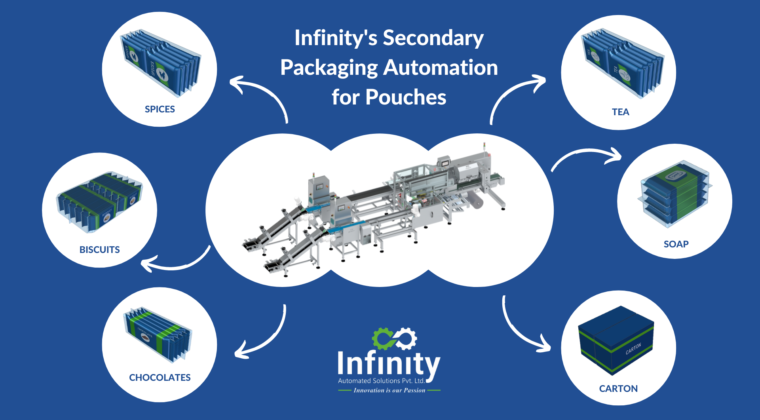

Applications of Infinity’s Automated Secondary Packaging Solutions for Pillow Bags

- Food and Beverage Industry: Ideal for packaging a variety of food products such as snacks, confectionery, and ready-to-eat items in pillow bags.

- Pharmaceuticals and Healthcare: Ensures precise and secure packaging of pharmaceutical products, maintaining hygiene standards and complying with regulatory requirements.

- Cosmetics and Personal Care: Automated solutions contribute to the efficient packaging of cosmetic products, maintaining product integrity and presentation.

- Household and Cleaning Products: Streamlines the packaging of household items, detergents, and cleaning products, ensuring consistency and minimizing packaging waste.

- Textile and Apparel: Efficient bundling and packaging of textiles and apparel, optimizing the logistics and presentation of these products.

- Electronics and Technology: Ensures secure packaging of electronic components and devices, protecting them during transit and storage.

- Retail and E-commerce: Ideal for optimizing packaging processes in retail and e-commerce, ensuring that products are efficiently packed and ready for distribution.

Infinity’s automated secondary packaging solutions cater to a wide range of industries, providing tailored solutions for diverse packaging needs and contributing to the overall success and competitiveness of businesses.

Conclusion:

Infinity’s automated secondary packaging solutions for pillow bags offer a blend of innovation, efficiency, and precision. Whether it’s bundling, shrink-wrapping, bagging, or cartoning, Infinity’s range of machines caters to the diverse needs of the packaging industry, ensuring a seamless and optimized packaging process for pillow bags.

Infinity’s Fully Automatic Secondary Packaging Solutions:

- Pouch Bundling & Wrapping

- Automatic Pouch Baler System

- Automatic Cartoning Machine

- Automated Case Packers

For more information, Contact us

- WhatsApp or Call: +91 8484922042

- Mail: info@infinitysols.com

- Website: www.infinitysols.com