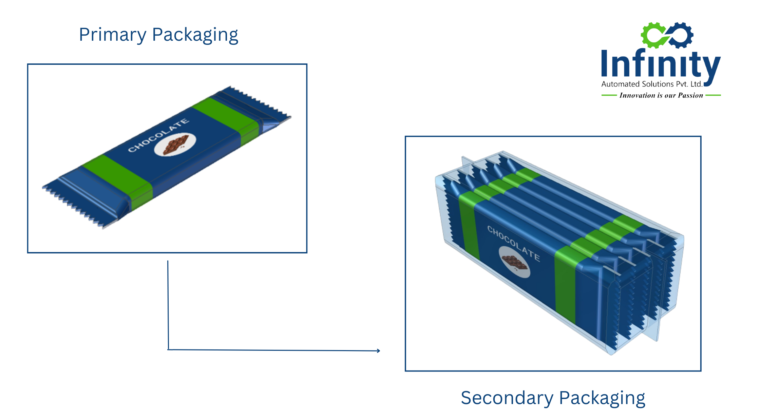

Automatic secondary packaging of chocolate refers to the process of using automated machinery and equipment to package individual chocolate products into larger containers or packages. This type of packaging is typically done after the chocolates have been wrapped or sealed individually.

How Does the Automatic Secondary Packaging of Chocolate Work?

Here’s a general overview of how the automatic secondary packaging of chocolate works:

- Conveying: The individual chocolate products are conveyed to the packaging area using a conveyor belt or similar system. They may be transported from a previous packaging stage or directly from the production line.

- Sorting: If necessary, the chocolates may go through a sorting process to ensure consistency in size, shape, or any other parameters required for packaging.

- Grouping: The chocolates are grouped together according to a predetermined quantity. For example, they may be grouped in sets of four or eight chocolates.

- Collating: The grouped chocolates are collated into the desired arrangement or pattern. This step ensures that the chocolates are properly aligned and positioned for packaging.

- Packaging material preparation: The packaging materials, such as cardboard boxes, trays, or sleeves, are prepared by the packaging machinery. This may involve cutting, folding, or forming the materials into the desired shape.

- Loading: The grouped chocolates are loaded into the prepared packaging materials. This can be done manually or using robotic arms or pick-and-place systems, depending on the level of automation.

- Sealing: Once the chocolates are loaded into the secondary packaging, the packaging material is sealed. This can involve various methods, including glue, heat sealing, or adhesive tapes.

- Labeling and coding: If required, labels or coding can be applied to the secondary packaging to provide product information, branding, or traceability.

- Quality control: Automated systems may include quality control mechanisms to ensure that the packaging is intact, the correct number of chocolates is present, and there are no defects or issues.

- Stacking and palletizing: After the secondary packaging is complete, the packaged chocolates may be stacked, palletized, and prepared for transportation or storage. Robotic systems can handle these tasks efficiently.

It’s important to note that the specific machinery and processes involved in automatic secondary packaging can vary depending on the scale of production, the type of chocolate products, and the desired packaging format. Manufacturers often customize their packaging lines based on their specific requirements.