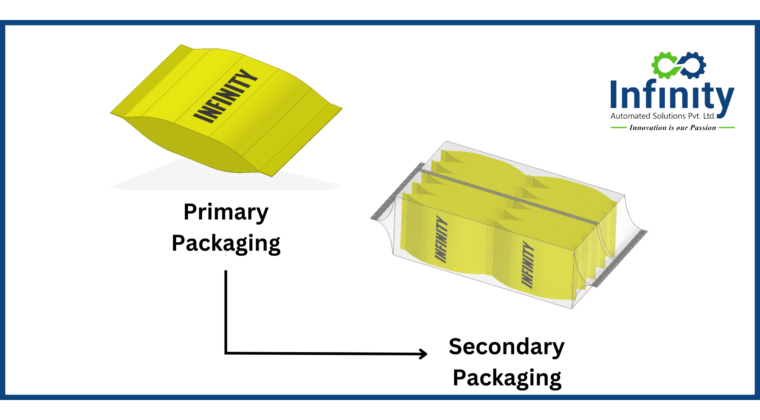

In primary and secondary packaging, primary packaging is the immediate packaging that comes into direct contact with the product, while secondary packaging serves as an outer layer to protect and display the primary packaging and product during distribution and retail. Let’s discuss this in detail.

Primary and Secondary Packaging

Primary Packaging

Primary packaging refers to the packaging that directly contains the product. It is the first layer of packaging that comes into direct contact with the product and is responsible for protecting, preserving, and presenting the product. Primary packaging is typically designed to be consumer-friendly and may include bottles, tubes, jars, blister packs, cans, or cartons. Its main purpose is to ensure the integrity and safety of the product during storage, transportation, and use.

Secondary packaging

Secondary packaging, on the other hand, refers to the packaging that contains and protects the primary packaging and product during distribution and retail display. It is typically designed for bulk handling, shipping, and shelf display purposes. Secondary packaging does not come into direct contact with the product and serves as an additional layer of protection. Examples of secondary packaging include cardboard boxes, shrink wrap, paperboard cartons, trays, and pallets. Its main function is to provide branding, information, and additional safety during transportation and storage.

Primary and Secondary Packaging: A Step-by-Step Guide

Here’s a step-by-step guide to primary and secondary packaging:

Step 1: Understand the Packaging Requirements

Before you begin the packaging process, it’s crucial to understand the specific requirements of your product. Consider factors such as product dimensions, fragility, perishability, and regulatory compliance. This will help you determine the appropriate packaging materials and design.

Step 2: Choose Primary Packaging Materials

Primary packaging refers to the immediate packaging that directly contains the product. Select packaging materials that are suitable for your product, considering factors such as protection, containment, and presentation. Common primary packaging materials include bottles, boxes, bags, jars, blister packs, or tubes.

Step 3: Design Primary Packaging

Create a design for your primary packaging that aligns with your brand and product requirements. Consider incorporating your brand logo, product information, and any regulatory labeling requirements. Ensure that the design is visually appealing and functional, providing ease of use and protection for the product.

Step 4: Test Primary Packaging

Before finalizing the primary packaging, perform thorough testing to ensure it meets the necessary standards. Test for factors like durability, compatibility with the product, and tamper resistance. Conduct drop tests, vibration tests, and any other relevant assessments to validate the packaging’s quality.

Step 5: Select Secondary Packaging Materials

Secondary packaging refers to the outer packaging that contains and protects multiple units of the primary packaging. Common secondary packaging materials include cardboard boxes, cartons, shrink wrap, or pallets. Consider factors such as stacking strength, ease of handling, and transportation requirements.

Step 6: Design Secondary Packaging

Design the secondary packaging to accommodate multiple units of the primary packaging. It should provide structural integrity, facilitate easy handling, and protect the primary packaging during transportation and storage. Incorporate relevant labeling, barcodes, and other necessary information for efficient tracking and identification.

Step 7: Test Secondary Packaging

Similar to primary packaging, conduct testing on the secondary packaging to ensure it meets the required standards. Test for factors such as stacking strength, load capacity, and resistance to external elements. Consider transportation conditions and potential impacts during handling.

Step 8: Ensure Regulatory Compliance

Make sure that both primary and secondary packaging complies with relevant regulatory requirements and industry standards. This includes labeling, warning signs, ingredient lists, and any other mandatory information specific to your product or market.

Step 9: Implement Packaging Processes

Establish a systematic process for packaging your products. This includes training employees on packaging procedures, quality control measures, and maintaining consistency in packaging standards. Implement checks at various stages to verify the accuracy and quality of the packaging.

Step 10: Monitor and Optimize

Continuously monitor the packaging process to identify any issues or areas for improvement. Gather feedback from customers, distributors, and internal stakeholders to make necessary adjustments and optimize the packaging design, materials, or processes.

Remember that specific packaging requirements may vary depending on the nature of your product and industry. Consulting packaging experts and adhering to relevant regulations will ensure you create packaging that protects your product while meeting consumer expectations.