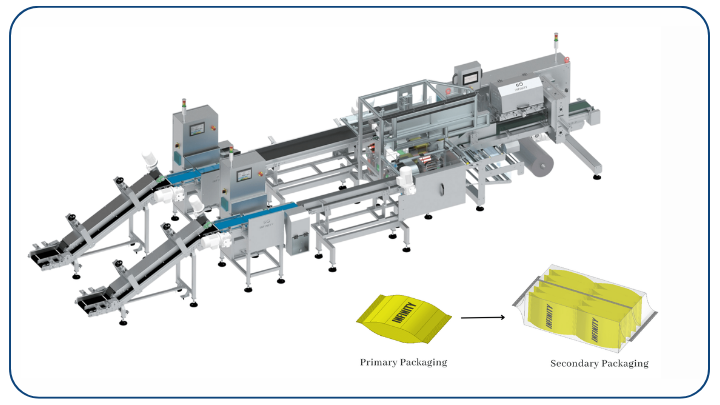

Secondary Packaging for Pouches (IBP-120)

Infinity’s Secondary Packaging for Pouches (IBP-120) revolutionizes the bundling and presentation of pouch products, offering seamless flow-wrapped packages at remarkable production speeds. Crafted from Heat Sealable Laminate, these secondary packs can also be transformed into shrink-pack variants. For flexible items, our sandwich conveyors maintain consistency and optimize pack size for efficient transport.

Leveraging Infinity’s cutting-edge RACETRACK system, our secondary packaging solution ensures swift product collation, gentle handling, and rapid changeovers. From 10 grams to 1 Kg, individual pouches are seamlessly bundled into larger pouches through integrated counting and bundling mechanisms, seamlessly interfacing with flow wrap systems. Operating at a pace of up to 20 secondary packs per minute, this system seamlessly integrates with your VFFS or HFFS machines.

Our sensor-driven technology guarantees precise product counts and facilitates 100% QA assurance, including optional check-weighing capabilities. Each secondary packaging solution is meticulously tailored to meet the specific requirements and application areas of our clients, ensuring optimal functionality and performance.

Key Features: Secondary Packaging for Pouches

- Automated Operation: Say goodbye to manual labor-intensive packaging processes. Our machine automates the secondary packaging of pouches, significantly reducing the need for human intervention and increasing overall efficiency.

- Versatile Compatibility: Designed to accommodate various pouch sizes, shapes, and materials, our machine offers unmatched versatility. From stand-up pouches to flat pouches, we’ve got you covered.

- Precision Handling: With advanced technology and precision engineering, our machine ensures gentle handling of pouches throughout the packaging process, minimizing the risk of damage or deformities.

- High-Speed Performance: Experience rapid packaging speeds without compromising quality. Our machine is optimized for high-speed operation, allowing you to meet demanding production requirements with ease.

- Customizable Configurations: Tailor the machine’s configurations to suit your specific packaging needs. From adjustable conveyor belts to customizable stacking patterns, you have full control over the packaging process.

- User-Friendly Interface: Featuring an intuitive user interface, our machine is easy to operate and requires minimal training. Simplify your workflow and maximize productivity with straightforward controls and clear instructions.

- Reliable Durability: Built to withstand the rigors of industrial packaging environments, our machine boasts exceptional durability and longevity. Invest with confidence in a reliable solution that delivers consistent performance day in and day out.

Benefits: Secondary Packaging for Pouches

- Increased Efficiency: By automating secondary packaging tasks, our machine enables you to accelerate production rates and reduce labor costs.

- Enhanced Product Quality: Minimize errors and ensure consistent packaging quality with our precise and reliable machine.

- Cost Savings: Streamline your packaging process and optimize resource utilization, leading to significant cost savings over time.

- Scalable Solution: Whether you’re a small-scale operation or a large manufacturing facility, our machine offers scalability to support your growing business needs.

Applications: Secondary Packaging for Pouches

- Food Industry: A secondary packaging for pouches is widely used in the food industry for packaging pouches containing snacks, confectioneries, bakery products, frozen foods, pet foods, and more. These machines handle the grouping, collating, and bundling of bags into BOPP, LD laminate film, ensuring product protection and easy handling during transportation.

- Pharmaceutical Industry: In the pharmaceutical industry, pouches are commonly used for packaging tablets, capsules, powders, and other dosage forms. secondary packaging for pouches is employed to pack these pouches into BOPP, LD laminate film, protecting against contamination, and tampering, and ensuring accurate product identification and traceability.

- Personal Care and Cosmetics Industry: The secondary packaging for pouches plays a crucial role in the personal care and cosmetics industry. Pouches containing products like shampoos, conditioners, lotions, creams, and other beauty and grooming items are often packed into BOPP, LD laminate film using these machines. They ensure consistent and attractive packaging, maintaining the product’s integrity and aesthetic appeal.

- Home Care Products: A secondary packaging for pouches is used for packaging pouches of household cleaning products, detergents, fabric softeners, and other home care items. These machines enable efficient packing into BOPP, LD laminate film, ensuring product safety and facilitating easy storage and transportation.

- Beverages Industry: In the beverages industry, secondary packaging for pouches handles pouches containing liquid products such as juices, energy drinks, and soft drinks. These machines can collate and pack pouches into BOPP, and LD laminate film, facilitating efficient distribution and minimizing product damage during transit.

- Pet Food and Animal Feed: Pouches containing pet food, animal feed, and treats are often packaged using secondary packaging for pouches. These machines can bundle pouches into BOPP, LD laminate film, providing convenient and durable packaging solutions for pet owners and retailers.

- Agricultural Products: Secondary packaging for pouches is utilized in the agricultural industry for packaging pouches of seeds, fertilizers, pesticides, and other agricultural products. They can collate and pack pouches into BOPP, and LD laminate film, ensuring proper handling and protection against moisture, pests, and environmental factors.