ICS-200 – Fully Automated Case Packer Machine & Automation for Strip ofPouches

Product Brochure

Get detailed specifications and technical information

Quick Model Access

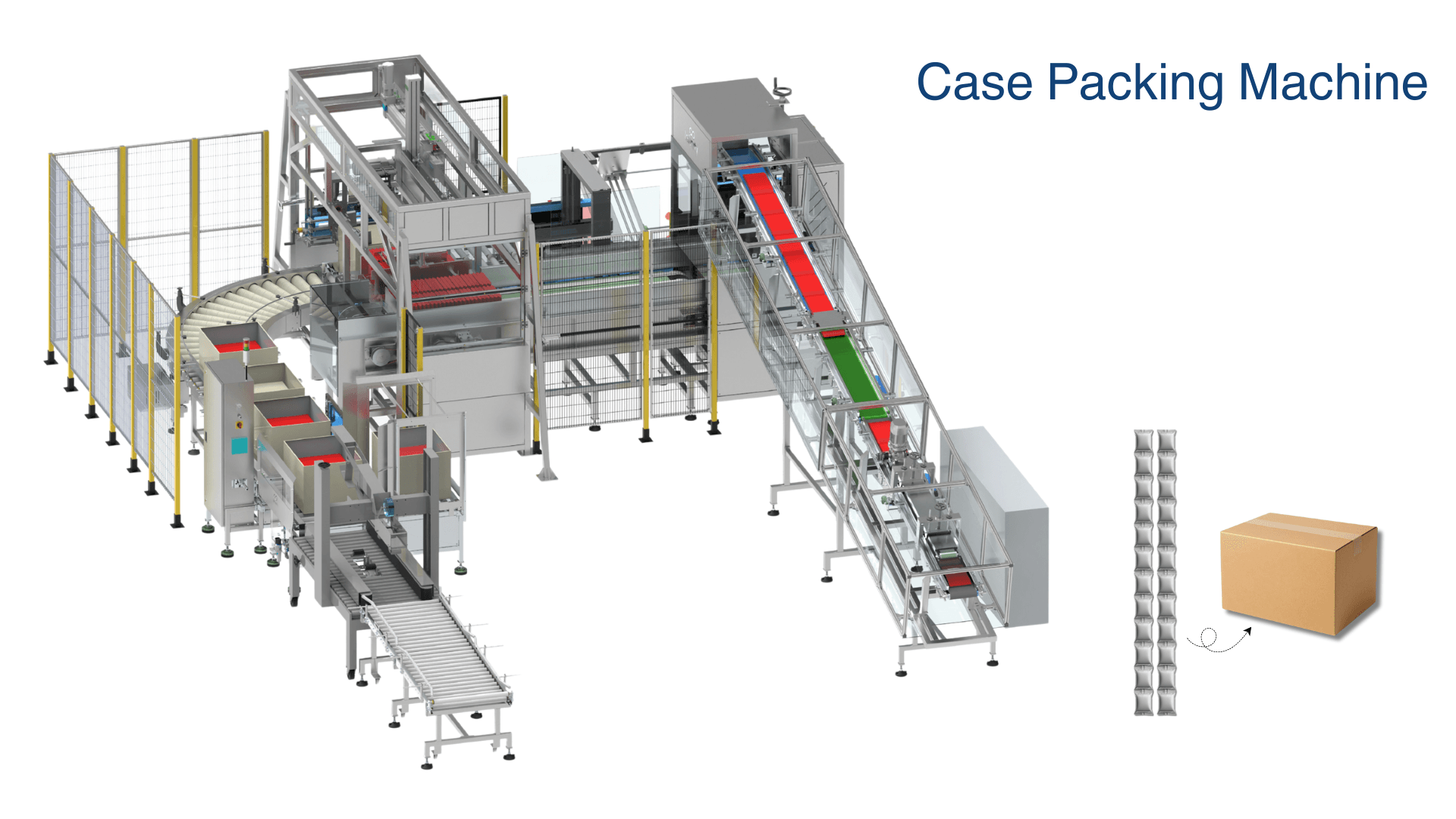

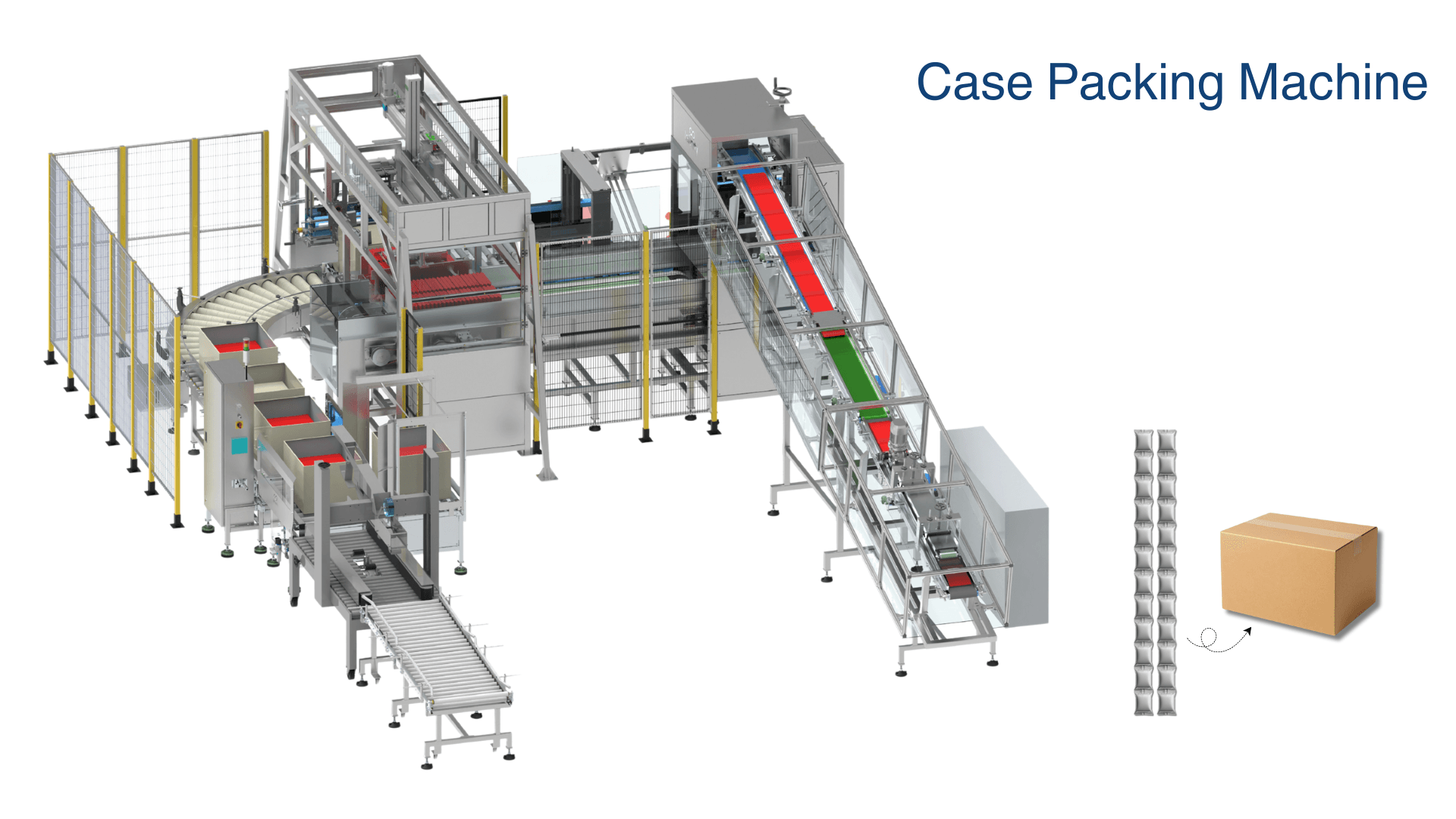

Infinity's Case Packer for Strip of Pouches, the ICS 200, is a high-performance secondary packaging machine designed for precise and hygienic packing of pouch strips into cartons. The system eliminates manual handling, improving accuracy, cleanliness, and overall packaging quality while delivering compact and aesthetically consistent carton packs.

Certifications

ICS-200 – Fully Automated Case Packer Machine & Automation for Strip of Pouches

ICS-200 – Fully Automated Case Packer Machine & Automation for Strip of Pouches

The ICS-200 is a high-performance case packer machine & automation solution from Infinity, designed specifically for strip of pouches. As a top-tier case packer machine manufacturer in India, Infinity has engineered this system for fully automatic end-of-line tertiary packaging: it collates strip pouches in a zig-zag or matrix formation, then loads them gently into shipper cartons using a Delta Robotic Pick & Place system with specialized grippers and vacuum suction cups. This 100 % servo-driven machine also supports inline finishing like taping, labelling, and check-weighing for a truly automated packaging flow.

Product Overview

Infinity's Case Packer for Strip of Pouches, the ICS 200, is a high-performance secondary packaging machine designed for precise and hygienic packing of pouch strips into cartons. The system eliminates manual handling, improving accuracy, cleanliness, and overall packaging quality while delivering compact and aesthetically consistent carton packs. Engineered for high-speed and continuous...

Features & Capabilities

Professional GradeAdvanced Features

Take-Up Conveying Technology

Creates stable product pitch for continuous strip flow.

Pendulum Collator

Aligns strip pouches into accurate matrix formations.

Delta Robotic Pick & Place

Robotic handling with mechanical and vacuum grippers.

Fully Integrated System

100% servo-driven system with carton erecting and sealing.

Inline Quality & Finishing

Supports check-weighing, taping, and labelling modules.

UI & Control

7" touchscreen with recipe memory and diagnostics.

Key Highlights

Take-up conveying for stable strip pitch creation

Pendulum collator for accurate matrix formation

Delta robotic pick & place with specialized grippers

100% servo-driven integrated system

Inline check-weigher, taping, and labeling options

Recipe memory and diagnostics via touchscreen HMI

Compact, open design for visibility and easy operation

Why ICS-200 is the Best Case Packers

The ICS-200 delivers high-speed output with precise handling for strip pouches. Its servo-driven motion, pendulum collation, and Delta robotic pick & place provide reliable, fully automated case packing in a compact footprint.

Benefits for Your Packaging Line

Improved efficiency with automated strip-to-case packaging

High accuracy from robotic pick & place handling

Inline check-weigher for quality assurance

Scalable and upgradeable modular options

Space-saving compact design

Lower labor cost and quick changeovers

Frequently Asked Questions (FAQ)

What type of products can the ICS-200 handle?

It is designed for strip pouches, including flat or pillow-style strips.

What throughput can it achieve?

The system supports input speeds of up to 200 PPM for strip pouches.

Can it work with my existing VFFS or HFFS line?

Yes. It is built for high-speed integration with VFFS or HFFS machines.

Is there inline quality control available?

Yes. Optional check-weigher, taping, and labeling modules can be integrated.

Does Infinity offer support and service in India?

Yes. Infinity provides local support, maintenance, and spare parts.

Related Models in case packers

ICP-120

ICP-120 Case Packer Machine

ICS-200

ICS-200 Case Packer for Strip of Pouches

ICB-120

ICB-120 Bottle Case Packer

Case Erectors & Sealers

Automatic Case Erectors & Sealers

Ready to Get Started?

Get detailed pricing and specifications for ICS-200 – Fully Automated Case Packer Machine & Automation for Strip of Pouches

Product Tags

Transform Your Packaging Process Today

Join 800+ satisfied customers who have revolutionized their packaging with our ICS-200 – Fully Automated Case Packer Machine & Automation for Strip of Pouches solution.