Industrial baler machines help businesses compress packaging waste at the source, turning bulky materials into compact, manageable bales. Instead of overflowing waste areas and frequent pickups, manufacturers gain cleaner workspaces, lower disposal costs, and better control over recycling operations. For companies handling high volumes of cartons, plastic films, pouches, and HDPE bags, a baler machine directly supports productivity and compliance.

Why Businesses Are Investing in Industrial Baler Machines

Packaging waste may seem like a small issue, but over time it leads to significant hidden costs. Loose cardboard and plastic occupy valuable floor space, slow down movement, and require constant manual handling. Frequent waste pickups increase transportation expenses and disrupt daily operations. In regulated industries, poor waste management can also impact audit readiness and brand reputation.

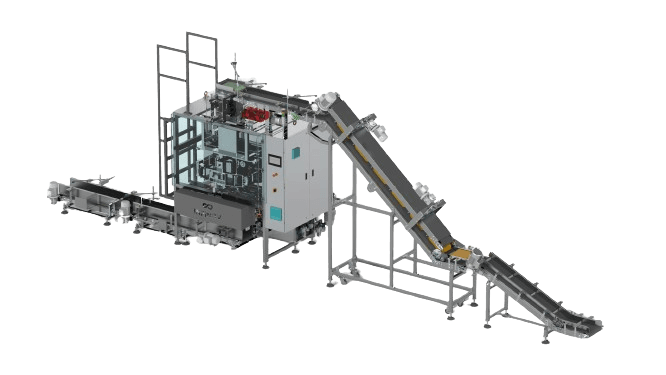

Infinity’s industrial baler machines are designed to address these challenges at their root. Installed inline with packaging or secondary packing systems, they compress waste immediately after generation. This approach reduces manual intervention, improves shop floor hygiene, and ensures waste is handled in a structured, compliant manner.

How Infinity’s Industrial Baler Machines Deliver Real ROI

Infinity Automated Solutions designs baler machines specifically for modern packaging environments where speed, automation, and reliability matter. These machines handle multiple waste types without frequent changeovers, making them ideal for FMCG, food, pharma, and logistics facilities.

By compressing waste into dense bales, businesses reduce waste volume drastically. This leads to fewer waste pickups, lower disposal charges, and reduced labor dependency. Over time, many plants also generate additional revenue by selling compacted recyclable materials such as cardboard and plastic films to authorized recyclers.

Infinity’s balers are built with automation compatibility in mind. They integrate seamlessly with VFFS machines, pouch packing lines, and secondary packaging equipment. Automated bale ejection and user-friendly controls ensure consistent performance with minimal operator involvement.

Key Advantages of Choosing Infinity’s Baler Machines

One of the biggest advantages of Infinity’s industrial baler machines is their ability to handle mixed packaging waste. From corrugated cartons to flexible pouches and HDPE bags, the machines are engineered for versatility. This is especially useful for plants managing multiple SKUs and packaging formats.

High compaction efficiency ensures waste occupies less space, making storage and transportation easier. Compact machine footprints allow installation even in facilities with limited floor space. Built-in safety features such as emergency stops, sensors, and interlocks ensure safe operation in high-throughput environments.

Most importantly, Infinity’s baler machines are designed for long-term performance. Durable construction, reliable components, and service support help businesses maintain uptime and protect their investment.

Industries That Benefit from Industrial Baler Machines

Industrial baler machines are widely used across sectors where packaging waste is generated daily. FMCG and food processing plants use balers to manage cartons, films, and pouch waste efficiently. Packaging and printing facilities rely on balers to control paper and plastic scrap. Logistics and distribution centers benefit from reduced handling and faster waste movement.

Pharmaceutical, healthcare, agriculture, and bulk commodity units also use baler machines to maintain cleanliness, meet compliance requirements, and improve operational efficiency. In all these industries, the goal is the same: controlled waste, lower costs, and smoother operations.

FAQs – Industrial Baler Machines

Are industrial baler machines suitable for high-speed packaging lines?

Yes, Infinity’s balers are designed to work seamlessly with high-output packaging systems.

Can these balers handle flexible packaging waste like pouches and films?

Yes, they are specifically engineered for flexible and mixed packaging materials.

Is investing in a baler machine cost-effective?

Most facilities achieve ROI through reduced disposal costs, labor savings, and recyclable revenue.

Do Infinity baler machines meet safety and compliance standards?

Yes, all machines follow industrial safety norms and environmental requirements.

Ready to Buy an Industrial Baler Machine?

If your facility is struggling with rising waste handling costs, space constraints, or sustainability targets, investing in an industrial baler machine is a practical next step. Infinity Automated Solutions offers automation-ready baler systems designed to match your production volume and waste type.

👉 Contact Us demo or price quotation today and see how Infinity’s baler machines can streamline your packaging waste management.

📞 Call / WhatsApp: +91 8484922042

📧 Email: info@infinitysols.com