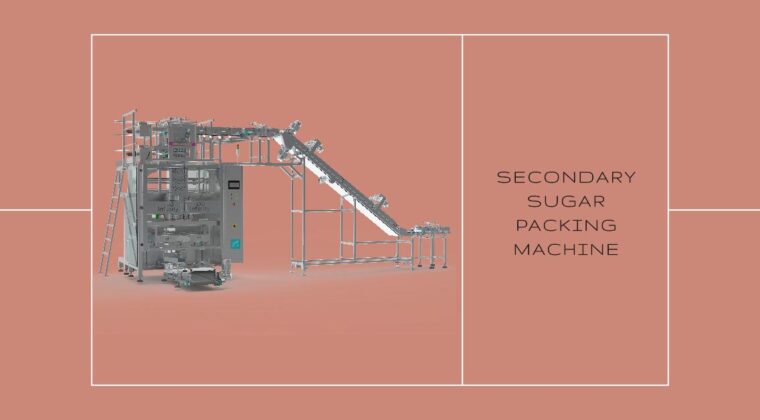

Infinity’s Secondary Sugar Packing Machine: Efficiency and Precision Redefined

In today’s fast-paced world, efficiency and precision are paramount, especially in the food and beverage industry. As consumer demands grow and safety regulations become stricter, businesses must adopt advanced technology to stay competitive. One such innovation is the secondary sugar packing machine developed by Infinity Automated Solutions. This cutting-edge machinery is designed to streamline the packaging process, ensuring that sugar is packed efficiently, accurately, and hygienically.

What is a Secondary Sugar Packing Machine?

A secondary sugar packing machine is an advanced piece of equipment used in the packaging industry to handle sugar products after they have been primarily packed (e.g., in pouches or sachets). This machine performs several critical functions:

- Collation: Gathering individual packs of sugar into a specified arrangement.

- Secondary Packaging: Placing the collated packs into secondary containers such as cartons or boxes.

- Sealing and Labeling: Ensuring the secondary packaging is securely sealed and accurately labeled for distribution.

Key Features of Infinity Automated Solutions’ Secondary Sugar Packing Machine

- High-Speed Operation: Designed for efficiency, this machine can handle high volumes, making it ideal for large-scale production facilities. Its high-speed operation ensures that production lines keep moving without bottlenecks, maximizing throughput.

- Precision and Accuracy: The machine uses advanced sensors and software to ensure that each pack of sugar is accurately placed and sealed. This precision reduces waste and ensures that customers receive the correct quantity every time.

- Hygienic Design: Hygiene is critical in food packaging. Infinity Automated Solutions’ machine is constructed with stainless steel and food-grade materials, ensuring it meets stringent hygiene standards. Easy-to-clean surfaces and minimal human contact further reduce contamination risks.

- Versatility: This machine can handle various packaging sizes and formats, making it adaptable to different product lines. Whether dealing with small sachets or larger pouches, the machine can be adjusted to meet specific needs.

- User-Friendly Interface: Equipped with a state-of-the-art touchscreen interface, the machine allows operators to control and monitor the packaging process easily. Intuitive software provides real-time feedback and diagnostics, simplifying maintenance and reducing downtime.

- Sustainability: In an era where sustainability is crucial, this machine is designed to minimize waste and energy consumption. Efficient operation reduces the carbon footprint, aligning with environmentally responsible practices.

Benefits to Businesses

- Cost Savings: By automating the secondary packaging process, businesses can significantly reduce labor costs and minimize packaging material wastage.

- Improved Product Quality: Consistent and precise packaging enhances product presentation and protects sugar from contamination and damage during transit.

- Enhanced Productivity: High-speed and reliable operation means that production schedules can be maintained, and customer demands can be met promptly.

- Compliance and Safety: Adherence to hygiene and safety standards ensures compliance with regulations, avoiding potential legal issues and recalls.

Real-World Applications

Many leading food and beverage companies have already integrated Infinity Automated Solutions’ secondary sugar packing machine into their production lines. These companies have reported improved efficiency, reduced costs, and higher customer satisfaction due to the enhanced packaging quality.

Conclusion

The secondary sugar packing machine by Infinity Automated Solutions represents a significant advancement in packaging technology. Its combination of speed, precision, hygiene, versatility, and sustainability makes it an invaluable asset for businesses looking to enhance their packaging processes. As consumer expectations evolve and industry standards rise, adopting such innovative solutions will be key to maintaining competitiveness and ensuring long-term success.

Invest in the future of your packaging operations with Infinity Automated Solutions and experience the difference that state-of-the-art technology can make.

For more information about Secondary Sugar Packing Machine, Contact us

- WhatsApp or Call: +91 8484922042

- Mail: info@infinitysols.com

- Website: www.infinitysols.com